What Is a Linear Actuator?

Comments Off on What Is a Linear Actuator?

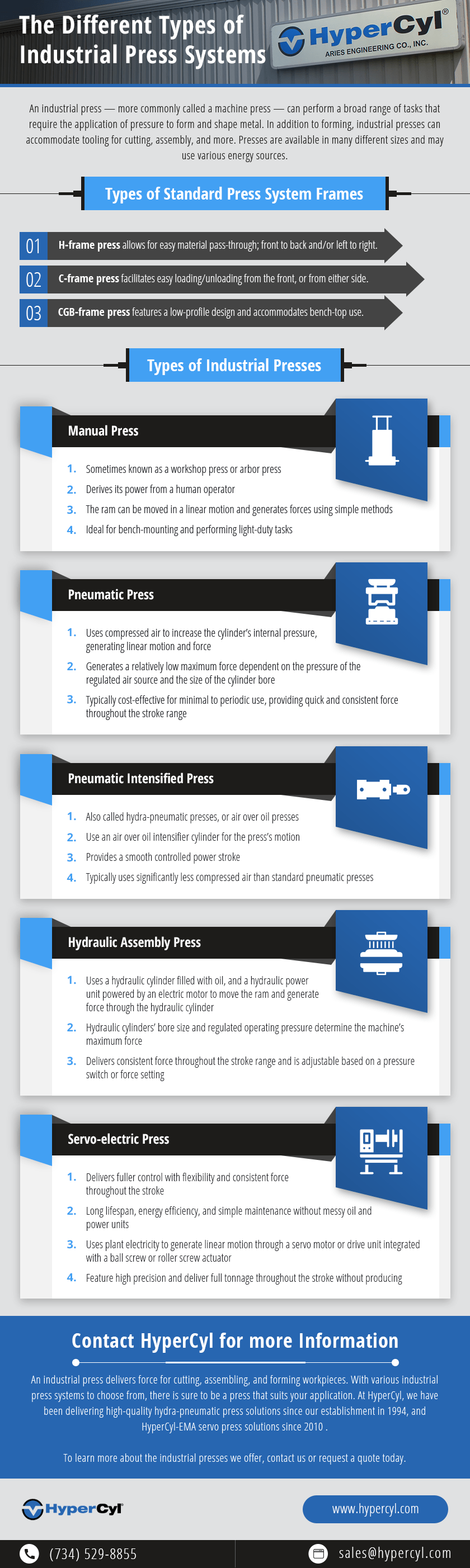

To differentiate between linear or rotary actuators, consider their motion profile. In the case of linear actuators, they generate push or pull movement along a straight line through rotary motion. Different types of linear actuators utilize energy sources such as electricity, pressurized hydraulic fluid, and compressed air or gas to power the motor that creates that rotary motion.

Operators have control over the speed of actuator movement, ensuring safe and efficient processing with high repeatability and positioning precision. Industries from aerospace and defense to agriculture and food and beverage make use of linear actuators for their cost-effectiveness and versatility in wide-ranging automation applications.

Different Types of Linear Actuators

To best suit the needs of these varied industries, engineers have developed three main types of actuators: mechanical/electromechanical, hydraulic, and pneumatic.

Mechanical and Electromechanical Linear Actuators

An external force activates a mechanical linear actuator, and an internal force for electromechanical linear actuators, but both derive linear motion by converting rotary motion. A motor such as a servo, a stepper, or a gearmotor utilizing AC or DC power typically fuels electromechanical linear actuators. Among electromechanical actuators, you’ll frequently find ball-screw, roller-screw (also known as planetary screws), or lead-screw designs. All three contain a rotating nut that moves linearly along a screw shaft. Using these actuators can provide more control over distance and force, though they are typically more expensive than other types.

Hydraulic Linear Actuators

Rather than an electric signal or manual motion, hydraulic linear actuators gain power from oil or other pressurized hydraulic fluid. You’ll find these in operation in machines and equipment situated in rugged environments and terrain, such as construction sites or mining excavations. Hydraulic linear actuators are ideal for high-force and high-power applications, especially where you require shock load capacity and consistent pressure. However, these actuators need a lot of power, often suffer from leakages, and are quite noisy. You can also damage hydraulic actuators if you operate them at high temperatures, and they require added parts for full functionality.

Pneumatic Linear Actuators

Pneumatic linear actuators convert compressed air or gas energy to produce straight motion. Speed and cost are the primary benefits of these actuators. They’re reliable and effective for applications that require the rate of linear motion in objects to be up to 60 inches per second. However, you’ll also need a compressor, which generates noise during operation, and pressure losses disqualify these actuators from applications needing absolute movement precision.

Features of Linear Actuators

Linear actuators have enjoyed widespread usage because of their reliability and versatility. Actuators pair with various power sources and come in numerous design configurations, such as screw, rod, or belt type, that provide the requisite force, precision, and acceleration/deceleration speed for multiple applications.

Requiring very little operator maintenance, actuators can have a long working life. You can deploy them in harsh environments, and they still provide high repetition, accurate positioning, and precision movements. Depending on the type you use, linear actuators can also be quite compact.

Industries and Applications for Linear Actuators

You will find linear actuators in many industries. Some of the most common are:

- Aerospace

- Agriculture

- Automotive

- Clean and renewable energy

- Food and beverage

- HVAC

- Marine

- Military

- Packaging

- Pharmaceutical

- Robotics

Actuators are critical components in many processes within these industries. For example, actuators capture and harness solar, tidal, and wind energy to power equipment and buildings. You can find them in automotive features ranging from power liftgates to sunroofs. Tanks use actuators to elevate their weapons systems. Also, factories in numerous industrial sectors use actuators to operate conveyor belts, robots, and other automated equipment.

High-Quality Linear Actuators From HyperCyl

For reliable, precision linear servo actuators for industrial processes or finished goods, Aries Engineering Company, Inc. and HyperCyl systems have what you need. Serving a diverse customer base in industries such as automotive, medical, and aerospace, AEC/HyperCyl provides both Ball Screw and Roller Screw actuators with superior performance in real-world assembly and forming applications, as well as our Application Test Lab for potential assembly evaluation.

Leveraging our expert engineers, product knowledge, and customer feedback, we ensure that HyperCyl fabricates electromechanical, hydraulic, and pneumatic linear actuator systems to meet the highest quality standards. To find out more about our actuator solutions, contact us or request a quote today.

There are two essential fixing points to consider when installing a pneumatic cylinder: the body and the piston rod end. How these points are fixed depends on the application.

There are two essential fixing points to consider when installing a pneumatic cylinder: the body and the piston rod end. How these points are fixed depends on the application.

Three major moving components

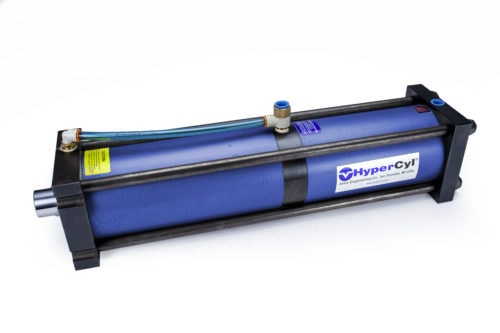

Three major moving components The full line (six series) of HyperCyl® hydra-pneumatic cylinders are designed for machine builders and OEMs to use in their own presses and automation, as well as for use in HyperCyl supplied presses. HyperCyl presses are available with “C” frames or “H” frames, unguided, two-column guided, or four-column guided upper bolsters, and bench-mounted, pedestal, or machine base configurations. Due to their modular design, machine designers can choose a simple frame and drive unit design that facilitates integration into a larger assembly process, or a turnkey design that incorporates automation technology, controls, and more.

The full line (six series) of HyperCyl® hydra-pneumatic cylinders are designed for machine builders and OEMs to use in their own presses and automation, as well as for use in HyperCyl supplied presses. HyperCyl presses are available with “C” frames or “H” frames, unguided, two-column guided, or four-column guided upper bolsters, and bench-mounted, pedestal, or machine base configurations. Due to their modular design, machine designers can choose a simple frame and drive unit design that facilitates integration into a larger assembly process, or a turnkey design that incorporates automation technology, controls, and more.