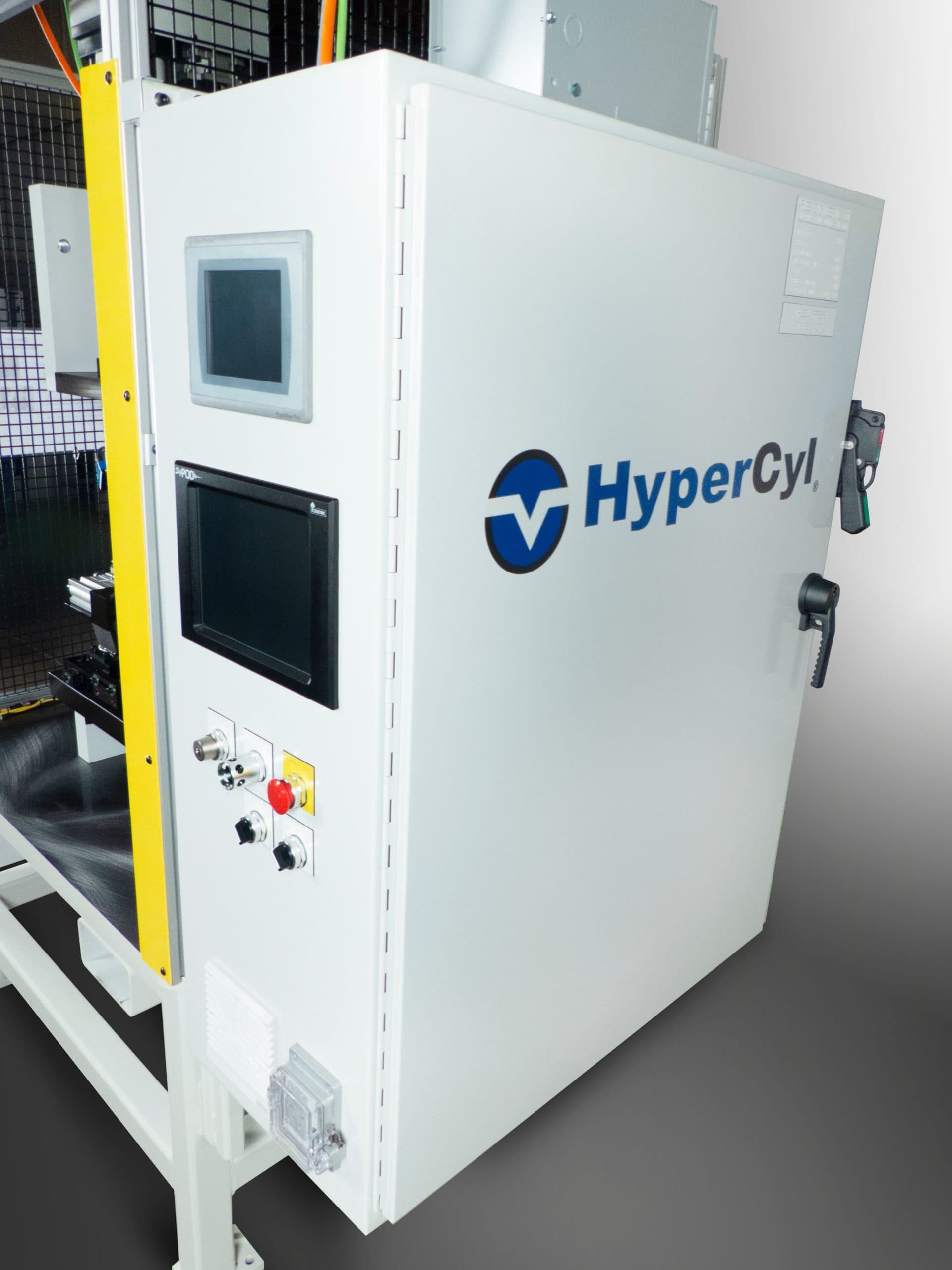

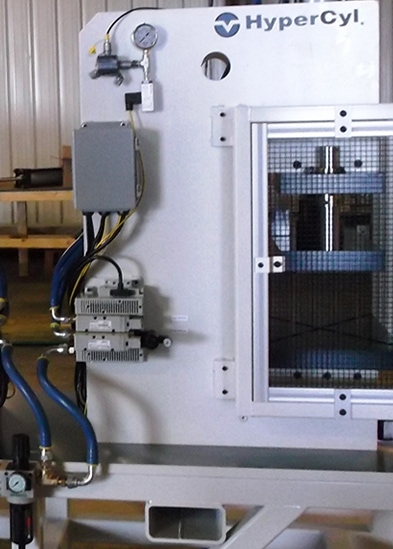

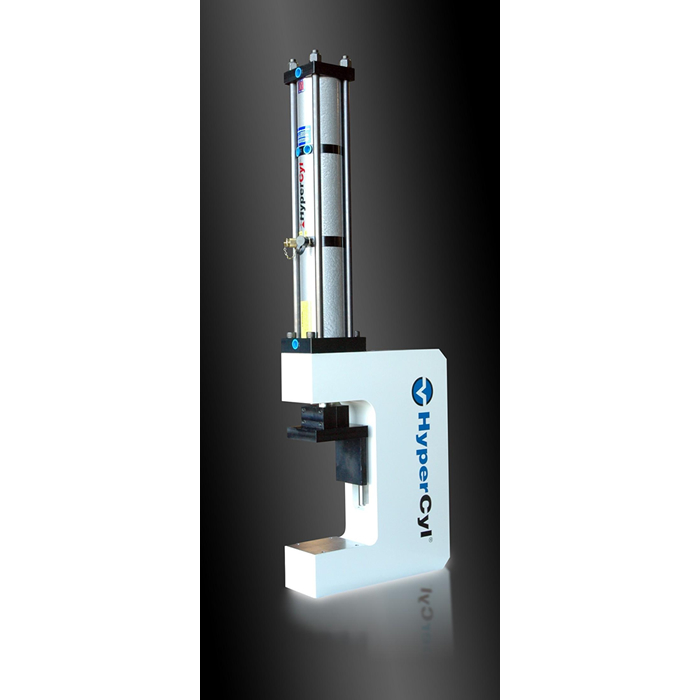

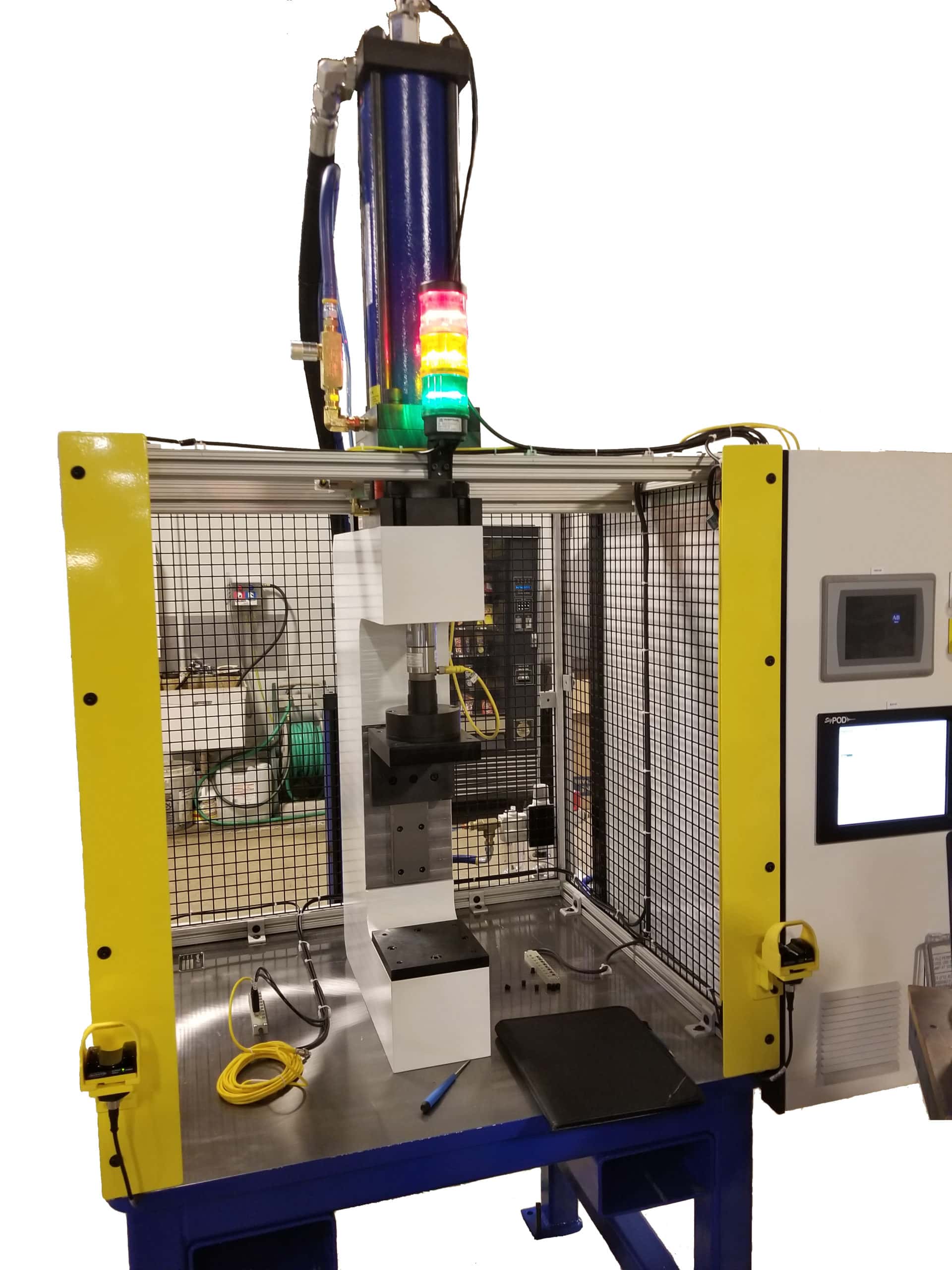

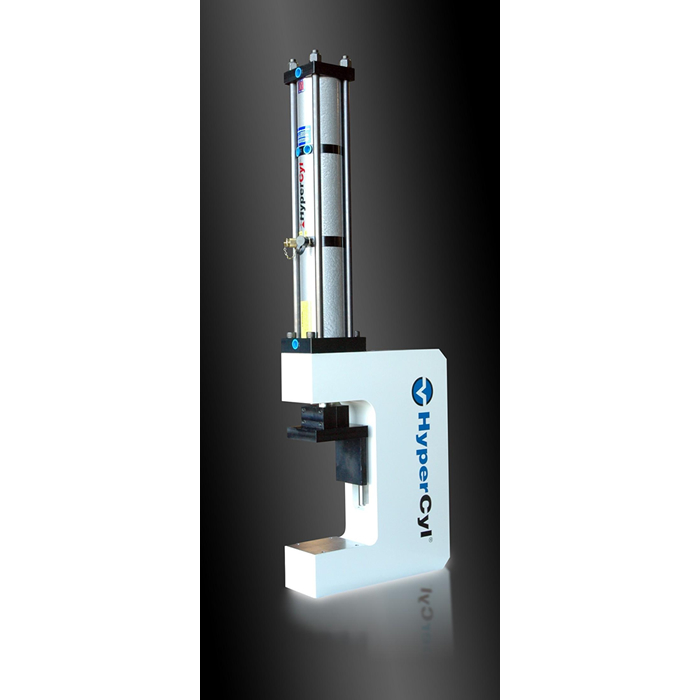

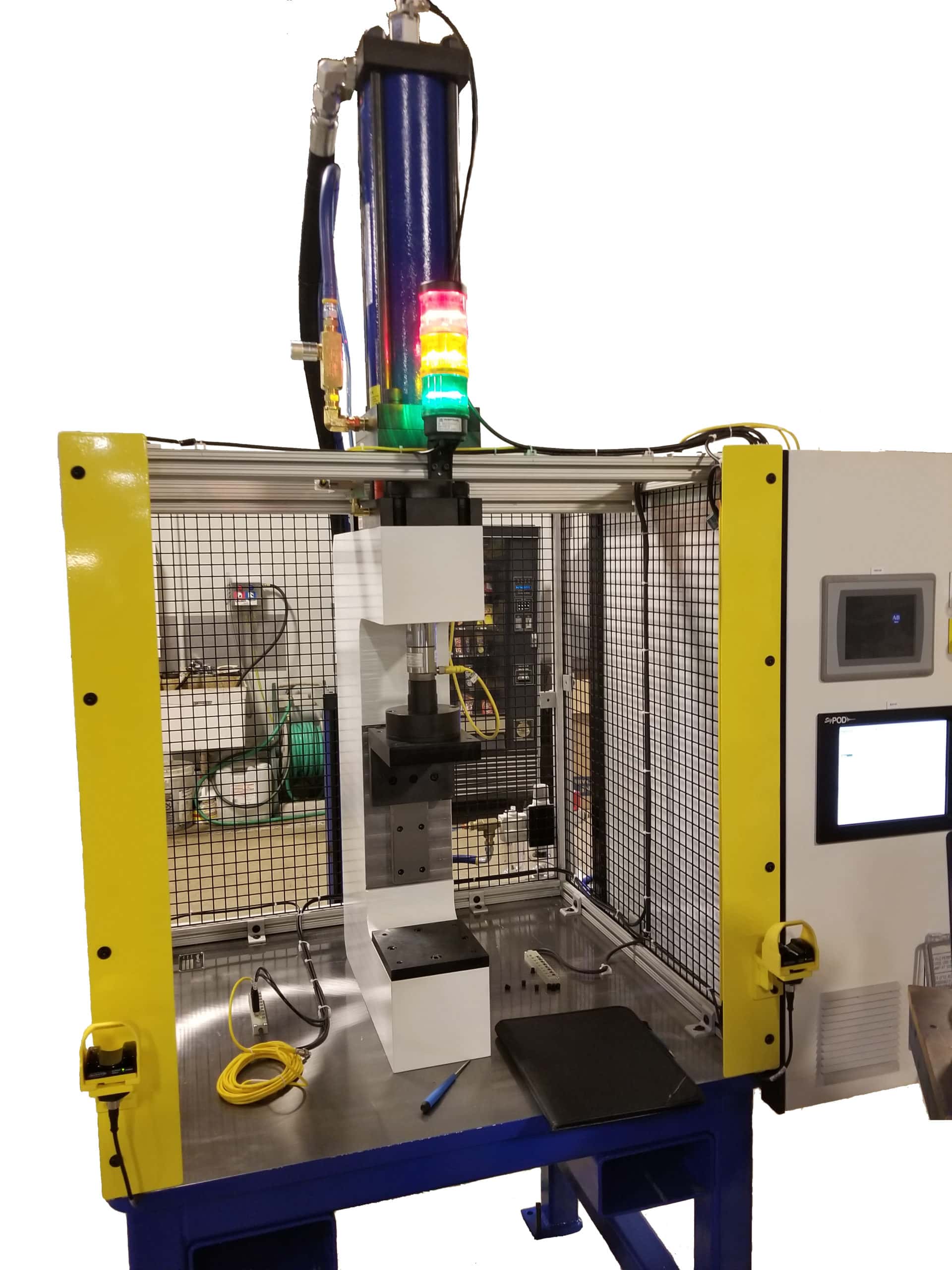

CGB LOW PROFILE PRESS

The CGB is a compact, high-performance press. Available in 2 to 30 tons, this bench-top design offers outstanding force and performance in a footprint just a few inches wide.

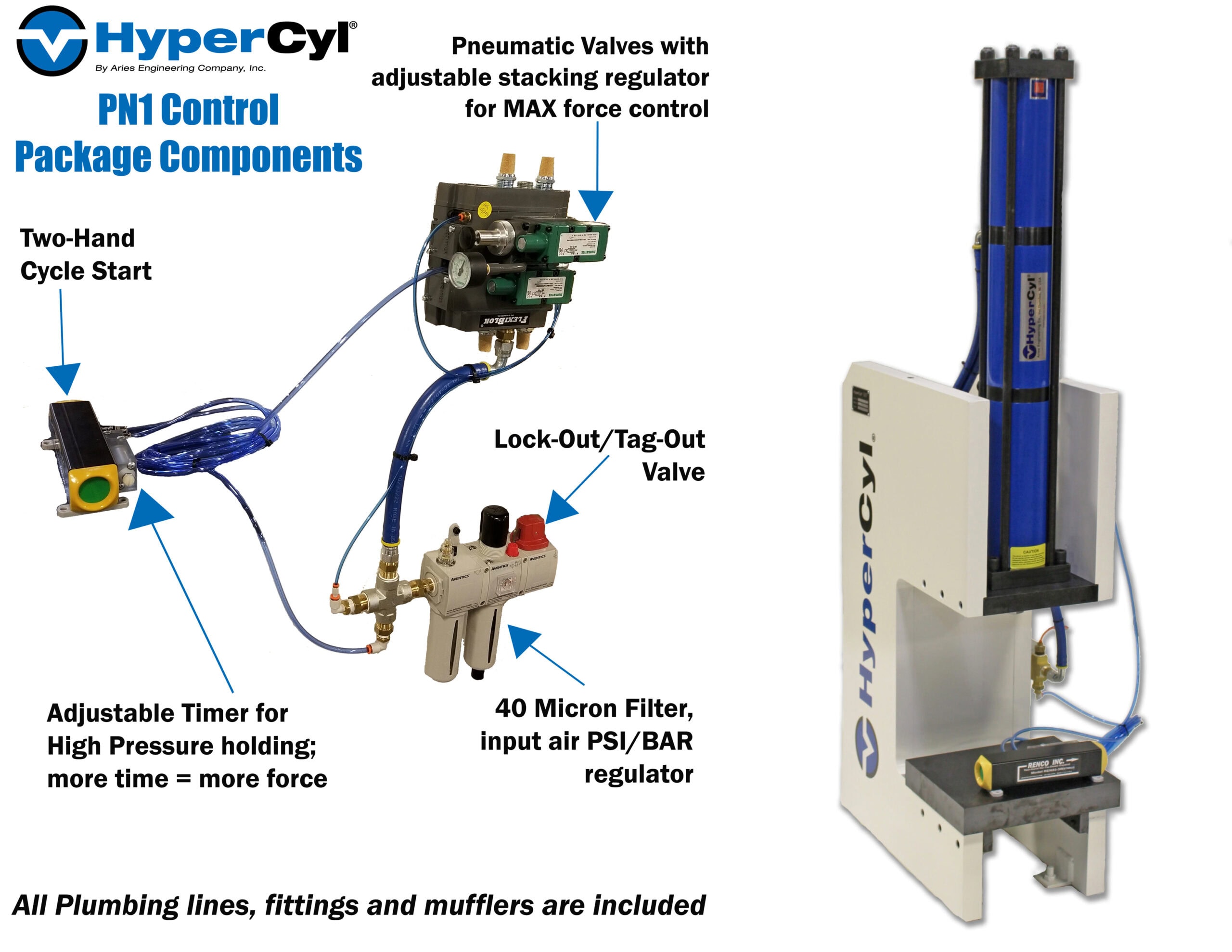

The upper bolster incorporates a high precision rail system for precise motion and rigidity. The removable machined tooling base comes with four tapped holes ready for user’s tooling. All HyperCyl cylinder versions are available on the CGB. All the benefits of hydra-pneumatic-cleanliness, medium to high forces, reduced contact shock, energy efficiency, low noise, and environmentally friendly-enhance the value of the CGB press. Riveting, clinching, piercing, joining, marking, and coining are just a few applications suited for this press solution. Numerous controls options and modifications are possible upon request. Made in the USA.

- AVAILABILITY: AVAILABLE

Please contact our sales team at 734-529-8855 for more information.

| Spec Sheet: | CGB Low Profile Press Spec Sheet |

|---|

Please contact our sales team at 734-529-8855 for more information.

Please contact our sales team at 734-529-8855 for more information.