Pneumatic cylinders are mechanical components that provide linear force to various devices and systems. They generate the force by applying compressed air to one side of a sealed barrel and exhausting it from the other side. This action causes the piston/rod assembly contained inside to extend or retract.

It is important to install pneumatic cylinders correctly. Otherwise, there is a risk of inaccurate or unreliable operation and premature failure. This is especially true for hydra-pneumatic cylinders, which generate high forces in a small package. As such, incorrect installation can lead to severe equipment damage and/or operator injury.

Below, we discuss how to install a pneumatic cylinder properly. Additionally, we highlight the importance of testing the system before putting it into operation and the precautions to take when performing installations.

How Do I Install a Pneumatic Cylinder Properly?

There are two essential fixing points to consider when installing a pneumatic cylinder: the body and the piston rod end. How these points are fixed depends on the application.

There are two essential fixing points to consider when installing a pneumatic cylinder: the body and the piston rod end. How these points are fixed depends on the application.

In static applications, the cylinder can be mounted to the machine bench and fixed rigidly to its structure. Both pneumatic and hydra-pneumatic cylinders are typically mounted with a rectangular front flange mount (also sometimes called an MF1 mount or FH mount) or tapped holes in the front of the face (also sometimes called an MR1 mount or UH mount) due to the high forces generated. However, some pneumatic cylinders use a semi-rigid trunnion mounting method (MT1) that utilizes body supports or pivots and clevis pins. It allows them to rotate as they follow the extension and retraction of the piston rod. In rare cases, a side lug mounting method (MS2T mount) may be used.

In complex linkage applications, the cylinder must be able to swivel on its mountings. There are several solutions to this mounting requirement. For example, a front clevis, central trunnion, or rear hinge can be used on the body of the cylinder to allow the cylinder and load system to achieve different degrees of balance. Alternatively, a clevis, front hinge, or universal eye can be used at the end of the piston rod to mount swivel attachments. If a trunnion mounting method is chosen, it is essential to ensure the cylinder can oscillate freely on the mountings and the pipe connections can flex when in use.

Some of the things to keep in mind when installing a pneumatic cylinder include:

- Minimize or eliminate side loading. Side loading is highly damaging to pneumatic cylinders. Ensuring the cylinder is correctly aligned and properly mounted can reduce the risk of it occurring. An alignment coupler or die set coupling can also eliminate or minimize side loading when attaching the rod end to the tooling.

- Lubricate the bearing slides and trunnions. The bearing slides and trunnions should be lubricated as per the manufacturer’s guidelines.

Why Should I Test the System?

Before putting a cylinder into operation, it is critical to test the entire system to ensure the component actuates with minimal resistance and the rod experiences minimal side loading. Testing operations can be conducted by using a flexible air line and blow gun to check the cylinder is installed properly and able to move freely at the published minimum operating pressures. For hydra-pneumatic cylinders, it is vital to test them in low pressures (approach and retract) without going into high pressures (intensification) to ensure the tooling and overall setup are aligned correctly. These testing operations should follow the manufacturer’s guidelines for sequencing the cylinder for approach, retract, and intensification.

What Precautions Should I Take When Installing Pneumatic Cylinders?

There are many considerations to keep in mind when installing a pneumatic cylinder. Be sure to take the following precautions to ensure safe installation:

- Avoid attaching unsupported loads directly to the piston rod. Use roller guides or a slide to support the load.

- Minimize bending moments. Suspend the rod end from a roller track or another form of external guidance if it has a long out-stroke and high shear weight. Install external bearings, or guides, to reduce side loading wherever possible.

- Align the pneumatic cylinder and guided loads properly. The use of alignment couplers, or die set couplers, will overcome minimal alignment issues.

- Use properly conditioned air, according to the manufacturer’s recommendations. Particulate filtration, removal of water (moisture), and other contaminants is important for nearly every manufacturer’s cylinders and pneumatic valves.

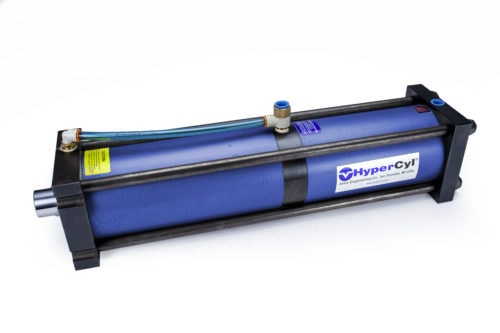

Hydra-Pneumatic Cylinder Solutions at HyperCyl

If you’re looking for hydra-pneumatic cylinders and presses for your assembly and forming operations, turn to the experts at HyperCyl. Equipped with more than 20 years of experience, we have the knowledge and skills to help you identify the right equipment for your needs. Our products are carefully designed, assembled, and installed to allow for greater process control, higher retract force, and better cost savings.

For more information about pneumatic cylinders or our product and service offerings, contact us or request a quote today.

Comments are closed