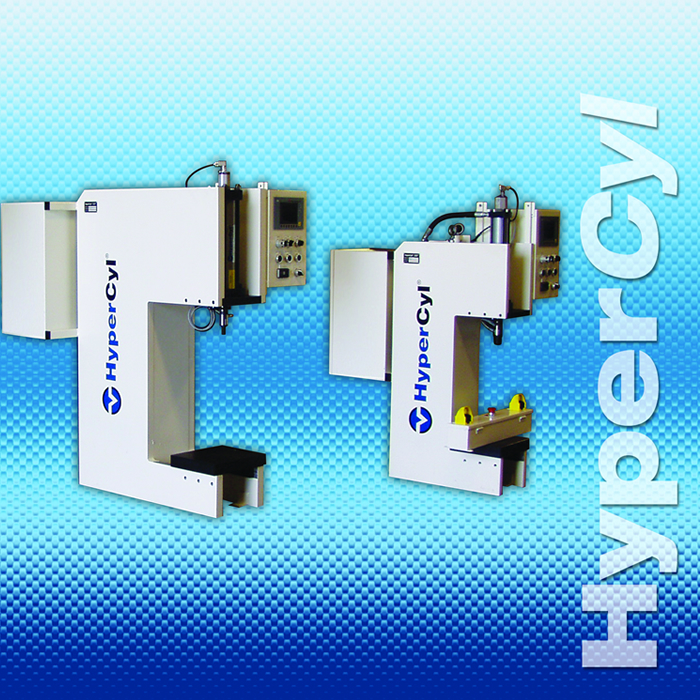

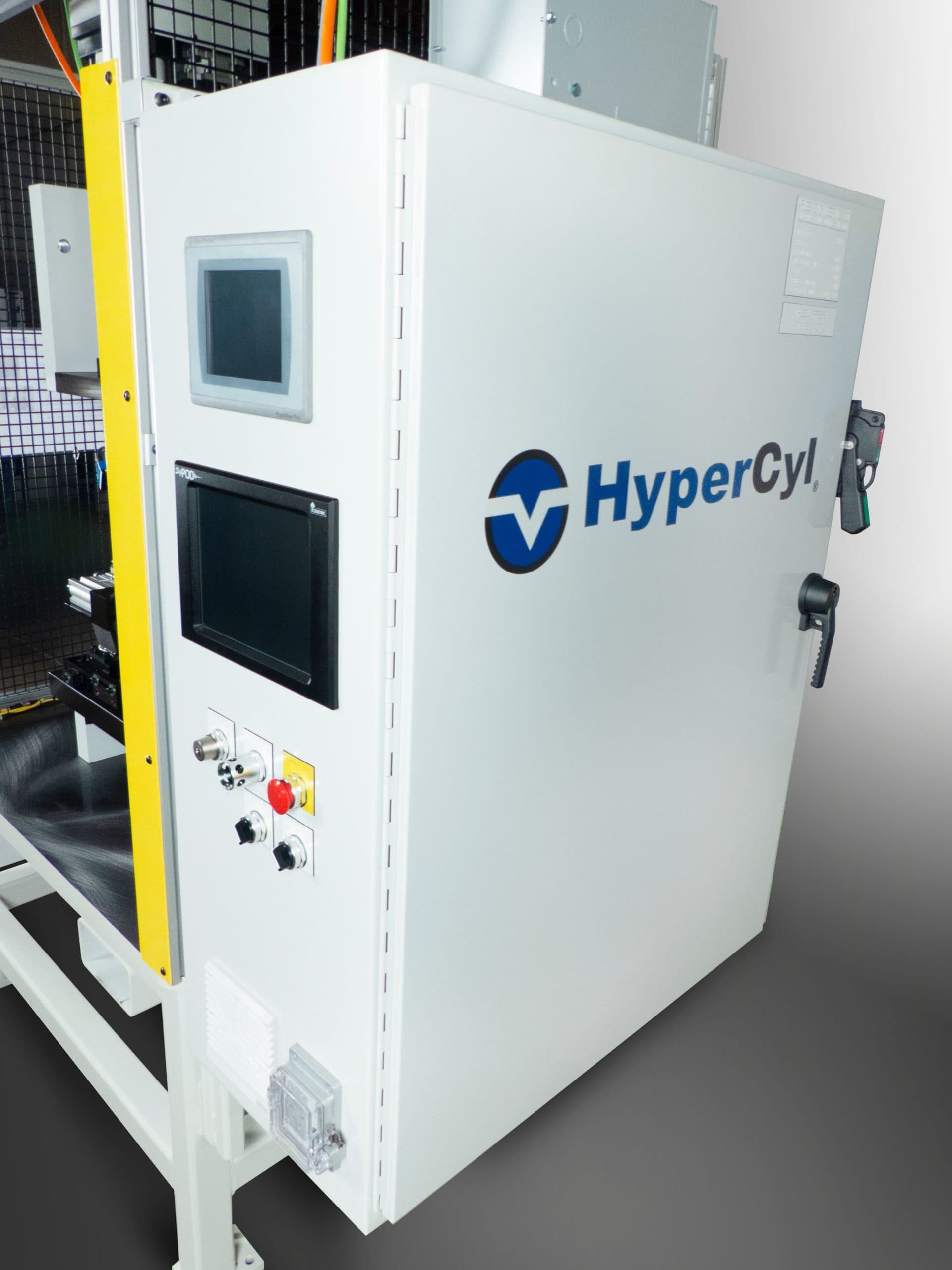

C-FRAME PRESS SERIES

C-frame presses are some of the most widely used presses. Their efficient designs make adjusting and maintaining these presses easier than other presses, and many applications depend on them. Also referred to as gap-frame presses, C-frame presses get their name thanks to the press’s C-like shape. C-frame presses are frequently used in manufacturing processes because they facilitate easy part loading and unloading for manual workers and automated solutions.

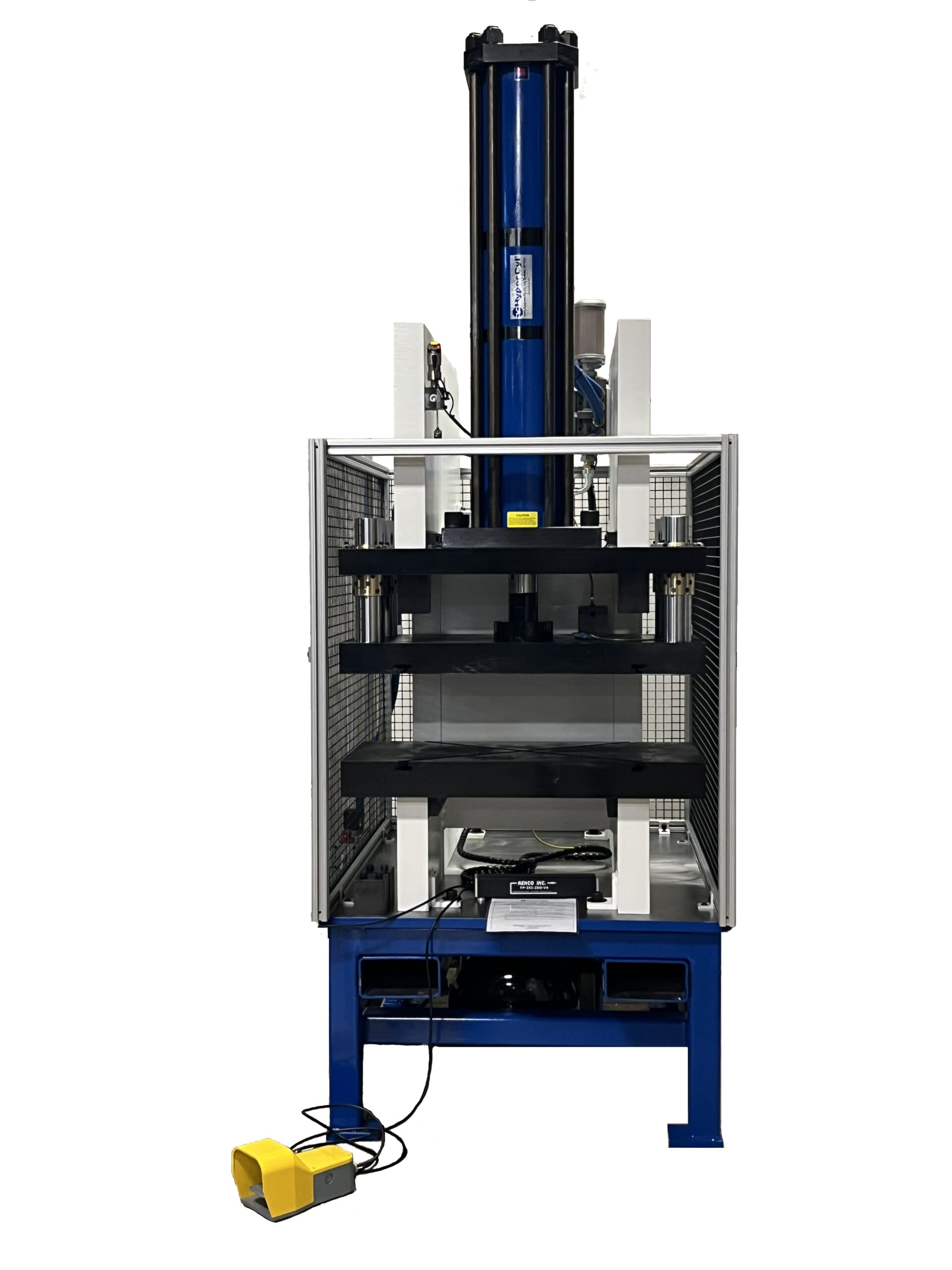

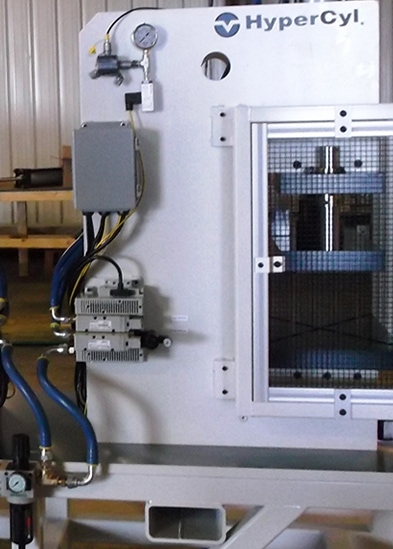

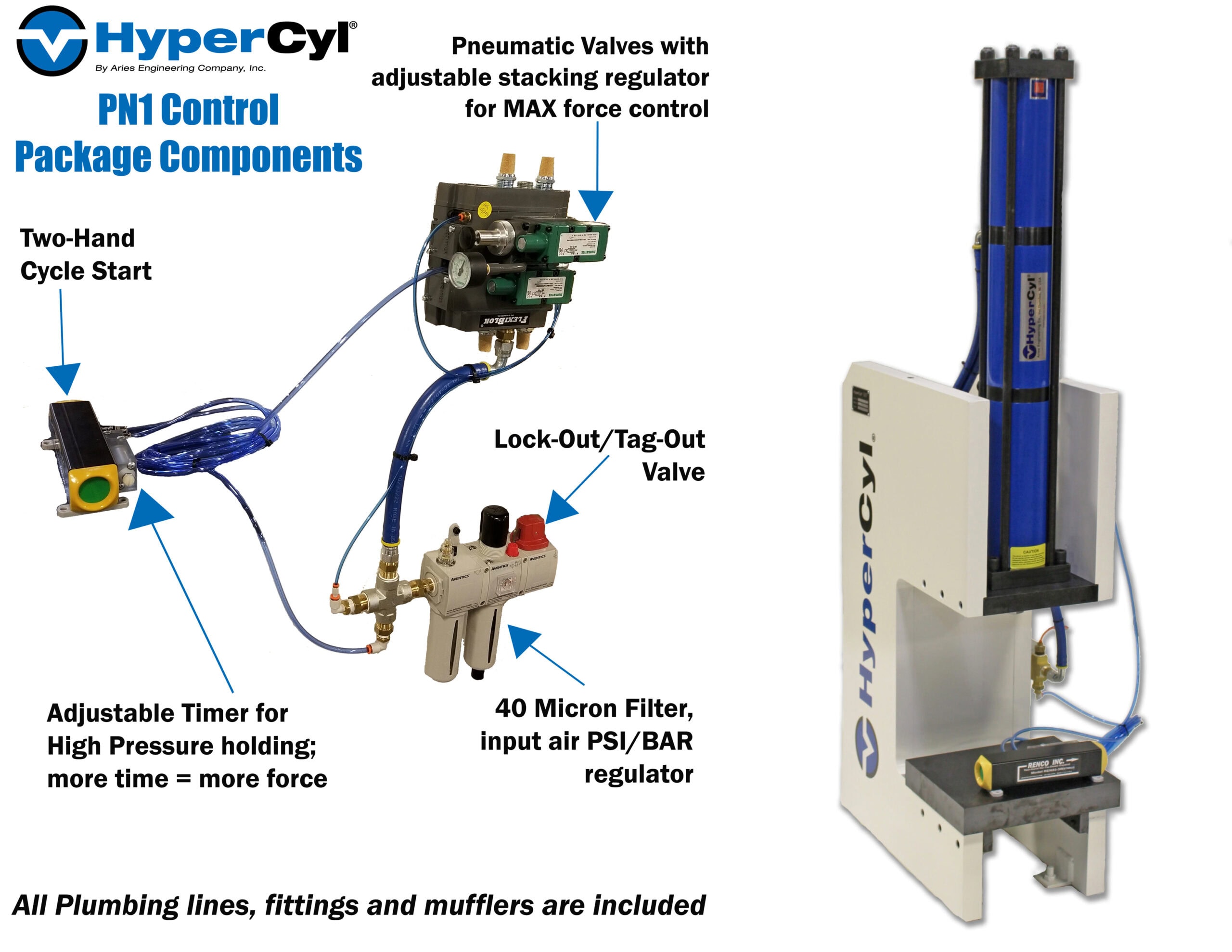

The basic C-frame press design consists of three components: a welded steel framework, a hydra-pneumatic cylinder or servo actuator, and upper and lower platens. Frames are available in either unguided and guided designs, depending on the application’s specific tooling considerations.

- AVAILABILITY: AVAILABLE

C-frame presses provide numerous advantages compared to other presses. Some of these benefits include:

- Easy access. A C-frame press has three access points to the working area, allowing for easier die maintenance and adjustments. The multiple access points also allow part loading from the left, right, or front of the cell.

- Affordable. C-frame presses are more cost-effective than straight-side presses, helping reduce the production line’s overall cost.

- Optimized space.With a narrow frame, C-frame presses take up less floor space and provide minimal stroke deflection.

| Spec Sheet: | C-Frame Press Spec Sheet |

|---|

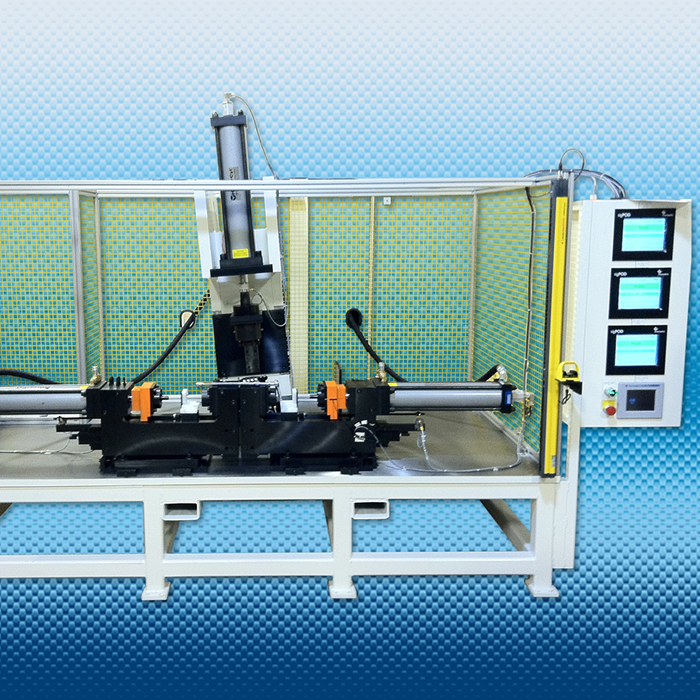

C-frame presses offer ideal performance in applications that require small bed sizes and tonnages ranging from 1-100 tons. C-frame presses can handle numerous operations including, but not limited to:

- Punching: Piercing or cutting openings, including holes in sheet material, plates, or other parts

- Blanking: Removing a piece of metal and retaining it while disposing of the rest as scrap

- Coining: Compression of all workpiece surfaces throughout closed-die systems

- Straightening: Stretching, twisting, or bending metal to straighten it, common for creating bars and tubes

- Forming: Transforming flat sheet metal parts into 3D parts

- Bending: Applying force to create angles in flat metal sheets or stock

- Drawing: Pulling metal through a tapered die to convert it into a thinner part

- Assembly: Fastening multiple parts together

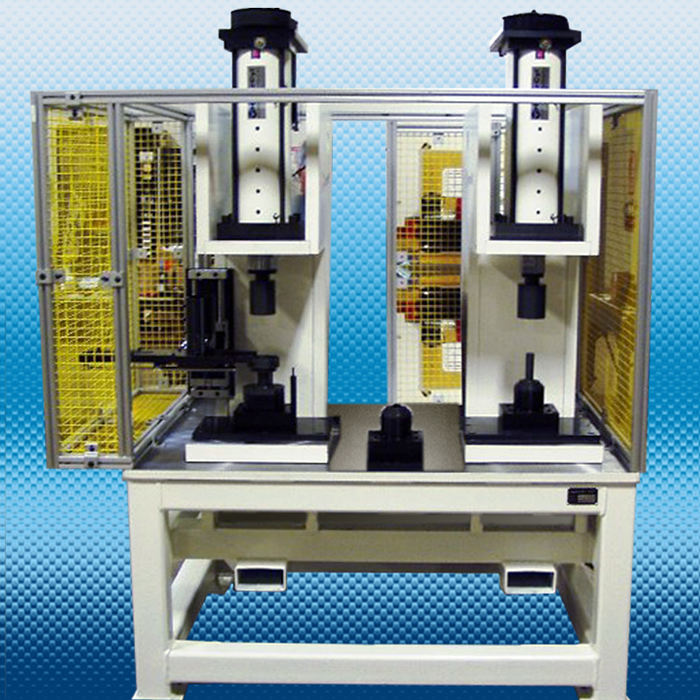

C-frame presses from HyperCyl typically support forming and assembly applications that require open fronts for simplified part loading and unloading. All of our frame designs are bead-blasted, normalized, primed, painted, and hold a very minimal deflection at full load, which is critical in assembly operations. We offer frames from 1-50 tons, including two-column unguided and four-column guided upper bolsters. We also offer custom sizes as high as 100 tons, and all of our C-frame presses meet current safety requirements.

In addition to other types of C-frame presses, we also offer CGB presses, a specific type of small-form C-frame press. As the most compact press offered by HyperCyl, our CGB presses are available from 2-30 tons with vertical guidance for anti-rotation and tool alignment. They consist of a one-piece, flame-cut, Blanchard ground steel frame, with HyperCyl hydra-pneumatic or HyperCyl-EMA drive units. Unlike larger C-frame presses, the CGB fits in tighter spaces to facilitate the stacking of multiple units side-by-side or where space is limited.

Regardless of application requirements and specifications, we have the right C-frame presses for your production line. To learn more about the presses we offer, contact us or request a quote today.