HyperCyl Spotlight: UTV Applications

Comments Off on HyperCyl Spotlight: UTV Applications

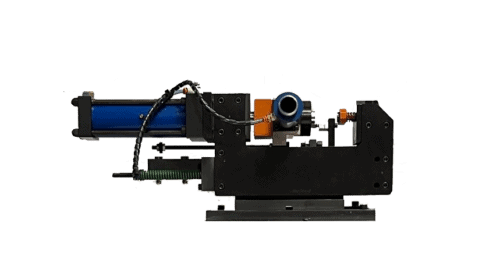

Roll Cage Pierce/Form: Typical End-forming and tube Piercing of UTV Roll Cage requires an Approximate Force Range 5-40 Tons depending on the details. Piercing requires internal expanding mandrels to reach long distances inside the tube body. End-forming varies dramatically based on the needs of each application but involves forming the end of tubes to various GD&T for mounting, safety, and other items. Best used with IntelliCyl for force/distance monitoring to ensure Quality is maximized.

REAR TRACK ARM BUSHING INSERTION: From the basic to the complex, we have seen it all regarding bushing insertions. Simultaneous running of LH & RH parts simplifies tooling setup and reduce part-to-part rates dramatically. Approximate Force for 1.500” – 2.500” bushing diameter ranges from 8-Tons to 15-Tons depending on the interference fit between the sleeve ID and bushing OD. Lubrication is sometimes necessary to reduce forces and ensure a good insertion. Lubrication is applied to the ID of sleeves or OD of bushing which reduces chatter during the installation process and provides a more accurate press-in.

WHEEL HUB BEARING AND STUD INSERTION: Wheel bearings are a critical function in the construction of UTV’s as they must be properly installed and seated or risk the longevity and ride comfort to the vehicle. Likewise, the wheel studs are installed with special fastening technology using serrations on the stud to withstand torque-out when attaching the wheel nuts. Force/ distance monitoring is almost always required for these critical components.

CONTROL ARM BUSHING INSERTION: Aries Engineering specializes in Control Arm construction due to our innovative power heads in Servo and Hydra- Pneumatic Self-Equalizing units.

These equalizing units are a necessity due to the small window between bushing sleeve ID’s. Backing up each sleeve prior to installation is required so as not to damage or twist the arm during bushing installations. Approximate Force Ranges from 8-20 Tons utilizing our IntelliCyl option for force/distance monitoring.

BALL JOINT INSTALLATION: Ball Joint installations typically require secondary retention to meet today’s safety requirements. Aries Engineering has patented a proprietary Snap-Ring installation process that automatically installs the Ball Joint then the snap-ring within a single process. Ordinarily this is a very manual process with handheld retaining ring pliers or circlip

pliers to ensure the clip is seated 100% and 360-degrees around the circumference. Approximate Force per Ball Joint can be as high as 20-Tons. IntelliCyl is required for force/distance monitoring of this critical component during the installation process.

PLASTIC FASCIA PIERCING/ DEGATING: Multiple components within the UTV require post-mold piercing to ensure proper alignment of fasteners and attachment points that cannot be done during the molding process. Piercing gas-cap holes to fog-lamp holes, hitch slots to lightening holes, we have Servo and Hydra-Pneumatic power units available that are well-suited. When a substance is melted and poured into casting molds, channels called gates allow the material to flow into the hollow spaces of the mold to form into a solid part. Removing the material that hardens in the channels so that just the finished piece remains is known as degating. We have developed methods to ensure this degating only removes excess material without damage to the end-product.

Aries Engineering/HyperCyl is a diversified manufacturer of Hydra-Pneumatic Cylinders, Servo Actuators, Presses, Pierce Units and Joining Systems designed for use in a wide range of assembly

and forming applications. HyperCyl has a place in virtually every segment of industrial production; from clean-room medical and electronic component manufacturing to heavy industrial piercing and forming. HyperCyl has a proven track record in thousands of applications as a clean, quiet, reliable, self-contained power source utilizing only compressed air to generate ample output forces from 3kN – 1,780kN.

Find out more how HyperCyl can help meet your application needs, email sales@hypercyl.com.

Flexibility, performance and cost have always been key factors in today’s expanding manufacturing marketplace. For decades hydraulic and mechanical presses were the only options for high-speed, high-force

Flexibility, performance and cost have always been key factors in today’s expanding manufacturing marketplace. For decades hydraulic and mechanical presses were the only options for high-speed, high-force