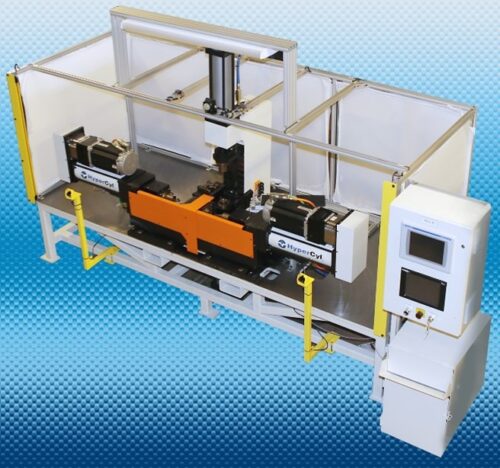

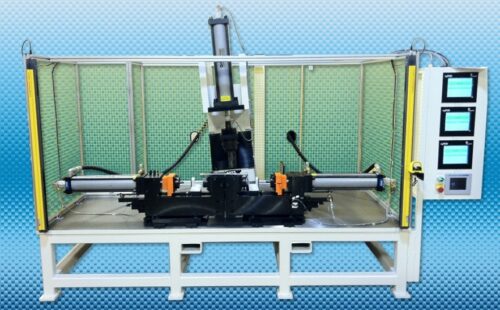

HyperCyl Case Study: HyperCyl-EMA Actuator Reduces Customer Costs and Down-Time

Comments Off on HyperCyl Case Study: HyperCyl-EMA Actuator Reduces Customer Costs and Down-TimeA food grade paper tray manufacturer contacted Aries Engineering/HyperCyl® to reduce electricity expenses when replacing (20) 30-Ton hydraulic presses. Their current hydraulic cylinders were costing them approximately $180,000 in electricity yearly, not including maintenance costs and the cost of hydraulic fluid disposal. The manufacturer chose the HyperCyl-EMA®, our Electro-Mechanical Actuator, which provided a cost savings to our customer in excess of $100,000 annually, when compared to the hydraulic units previously used. Extreme Accuracy, Quality, and cost savings allows HyperCyl-EMA® to compete with any electric or hydraulic cylinder on the market!

The ability to apply force the entire length of the stroke makes HyperCyl-EMA® widely suitable for use in applications such as Pressing, Stamping, Assembly line or Robot installations and other various high force/highly accurate projects. HyperCyl® currently provides high force solutions to many diverse industries such as Medical, DOD, Munitions manufacturing, Tier 1 automotive companies and Aerospace manufacturing. Standard equipment includes the Emerson UniMotor, Internally mounted temperature- compensated Load Cell, Standard Internal Non-Rotate and End of stroke Proximity sensors. EMA is available in standard stroke lengths of 8.00” and 14.00”. Please contact the factory for additional stroke availability. We also offer the HyperView Press signature analysis controller, with 10” TFT touch-screen for Live-Time Quality Control over your application while in-process.

These exceptionally accurate actuators (.0001”) have a high rate of repeatability and create a cost- effective alternative to hydraulic units because of their no fuss installation, limited maintenance schedule and user-controlled adjustability. Complete tooling-ready TurnKey presses, as well as standalone actuators are available upon request.

Find out how HyperCyl can meet your application needs, email [email protected].

dimpling, peening, swaging, inserting, clinching, pressing, staking, piercing, punching, marking, bending, and forming. When coupled with the IntelliCyl option, (load cell and LVLT) force distance monitoring is available.

dimpling, peening, swaging, inserting, clinching, pressing, staking, piercing, punching, marking, bending, and forming. When coupled with the IntelliCyl option, (load cell and LVLT) force distance monitoring is available.