“Punching and Shearing” Tips and Tricks

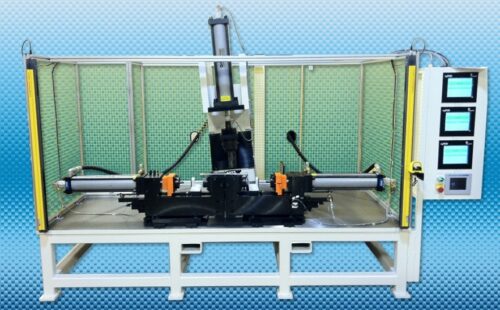

Comments Off on “Punching and Shearing” Tips and TricksAries Engineering/HyperCyl is a diversified manufacturer of Hydra-Pneumatic Cylinders, Servo Actuators, Presses, Pierce Units and Joining Systems designed for use in a wide range of assembly

and forming applications. HyperCyl has a place in virtually every segment of industrial production. HyperCyl has a proven track record in thousands of applications as a clean, quiet, reliable, self-contained power source utilizing only compressed air to generate ample output forces from 3kN – 1,780kN.

The formula to calculate punching force is quite simple:

Force = Hole Perimeter (length of cut) x Material Thickness (aluminum, steel, stainless) x Shear Strength or Tensile Strength (depends on type of punch being used). You must make sure that you keep your units consistent between Metric and Imperial.

Metal Forming

Forces required for metal piercing can be calculated as follows:

L= Length

T= Thickness of Material

S= Shear Strength of Material

L x T x S = Force Required

(stripping force= 10% of Pierce Force)

Stripping force is the force required to typically remove or retract the punch after it has pierced the material.

Example:

3/8 ” (.375″) hole through .032″ thick CRS (cold rolled steel)

L= 1.178 (.375 x 3.141)

T= .032

S= 55,000

1.178 x .032 x 55,000= 2090 lbs.

Here are some helpful tips and tricks for punching and shearing applications:

*While the ultimate Tensile strength is used for initial calculations for flat punch designs, the formula for using full tensile strength is applied at the onset to establish a WORST-CASE scenario for sizing our cylinders. Real life tensile can vary based on mold/forming time, cooling time, work hardening (if applicable) and a host of other miscellaneous factors. We don’t see as much variation with Aluminum castings as we do with steel.

*We can provide parts-testing data and extrapolate from our testing for a 0.25”, 0.375”, and 0.500” nominal punch holes to determine the actual tensile/shear strengths and calculate real life forces, factoring in the flat punch or shear punch designs.

*Not everyone uses Shear in the punch head, MOST use a flat punch so it can be sharpened easily and reused for many years. When using SHEAR in your punch head, the Shear Strength can be used for force calculations.

*In all piercing applications, a “stripper” or positive force on the part DURING punching operation should be considered so the part can remain located in nesting during retraction of the punch from part. If absent from your design, the part will retract with the punch during retract.

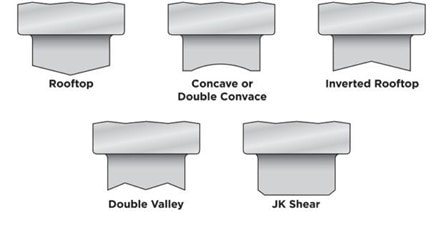

*There are numerous versions of shearing punch designs which directly correlate to forces required:

-High angle, straight cut (think scissors)

-Rooftop

-Inverted Rooftop

-Inverted Rooftop

-Double Valley

-JK Shear (flat punch, using Tensile strength, NOT shear strength)

Find out more how HyperCyl can help meet your application needs, email sales@hypercyl.com.

dimpling, peening, swaging, inserting, clinching, pressing, staking, piercing, punching, marking, bending, and forming. When coupled with the IntelliCyl option, (load cell and LVLT) force distance monitoring is available.

dimpling, peening, swaging, inserting, clinching, pressing, staking, piercing, punching, marking, bending, and forming. When coupled with the IntelliCyl option, (load cell and LVLT) force distance monitoring is available.