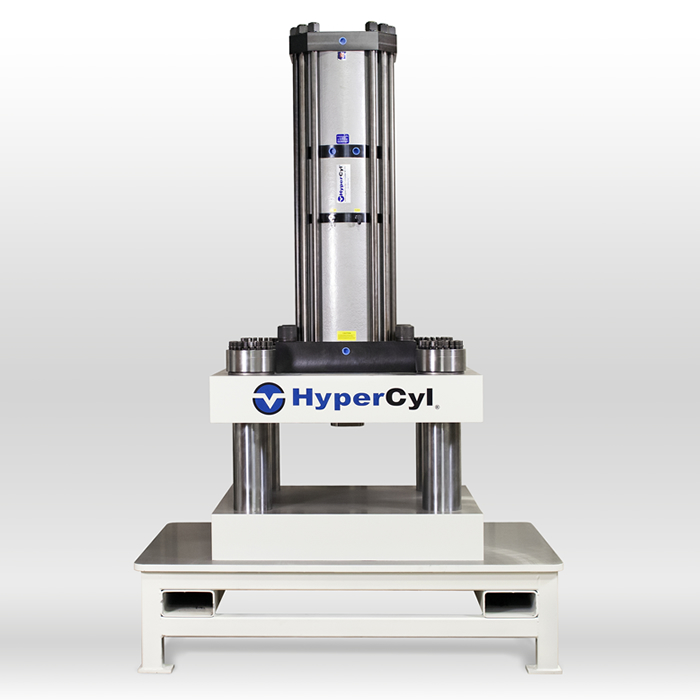

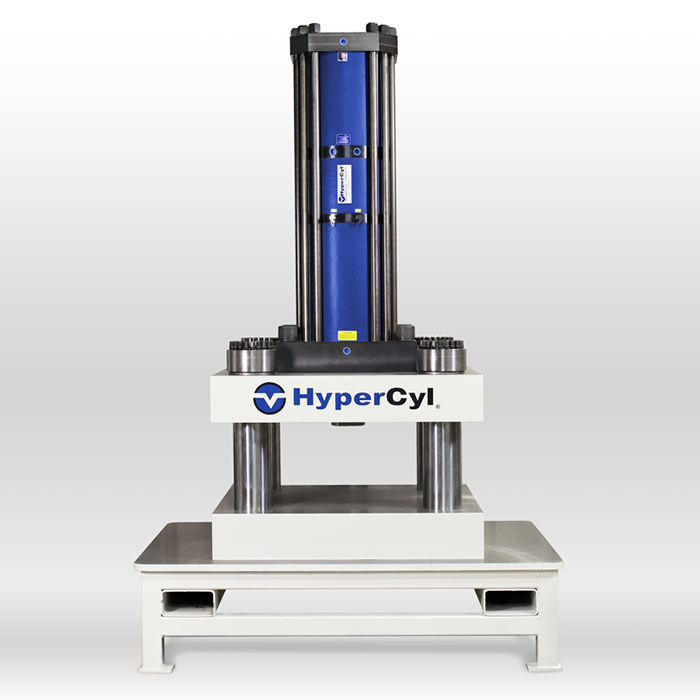

H-FRAME PRESS

H-frame presses are so named for their H-like shape. They consist of a steel frame, posts, a press cylinder, and, optionally, a movable middle bolster. Since they can have two or four posts, which can serve as a guide for a moving platen, they are also sometimes referred to as two-column or four-column presses.

These presses are primarily used for assembly and forming applications that require a pass-through design for part loading and unloading operations. Materials can be passed from front to back and/or left to right before and after force is applied. The force required for the operation influences both the frame design and the cylinder size of the unit.

- AVAILABILITY: AVAILABLE

H-frame presses have several advantages over other types of presses, such as:

- Simple design. The design of H-frame presses is simple, which means these press units take less time to engineer. As a result, they are often available at lower price points than C-frame presses.

- Easy material pass-through. H-frame presses have an open front, back, left, and right side. This design enables workers to load and unload material in any direction.

- Large tooling suitability. H-frame presses can accommodate tooling with large footprints, such as rule dies.

- Effective operation. The accuracy and precision of H-frame presses make them an effective option for various pressing needs.

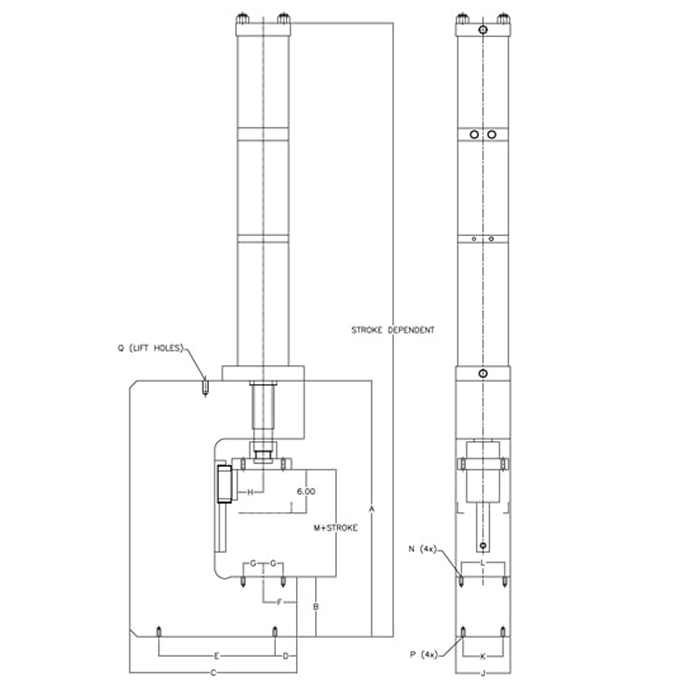

| Spec Sheet: | H-Frame Press Spec Sheet |

|---|

H-frame presses can meet high-quality standards in nearly any forming and assembly application. Typical operations for them include:

- Bending: Creating angles in the material to form V, U, or channel shapes

- Blanking: Cutting the component out of sheet or strip stock

- Forming: Deforming the material into a 3D shape

- Straightening: Bending, stretching, or twisting the material into a straight form

- Piercing: Adding holes or slots to a component

- Cutting: Removing material from a stock piece to achieve the right size and shape

- Stamping: using a tool and die set to form the material into the desired net shape

- Assembly: joining two or individual components together

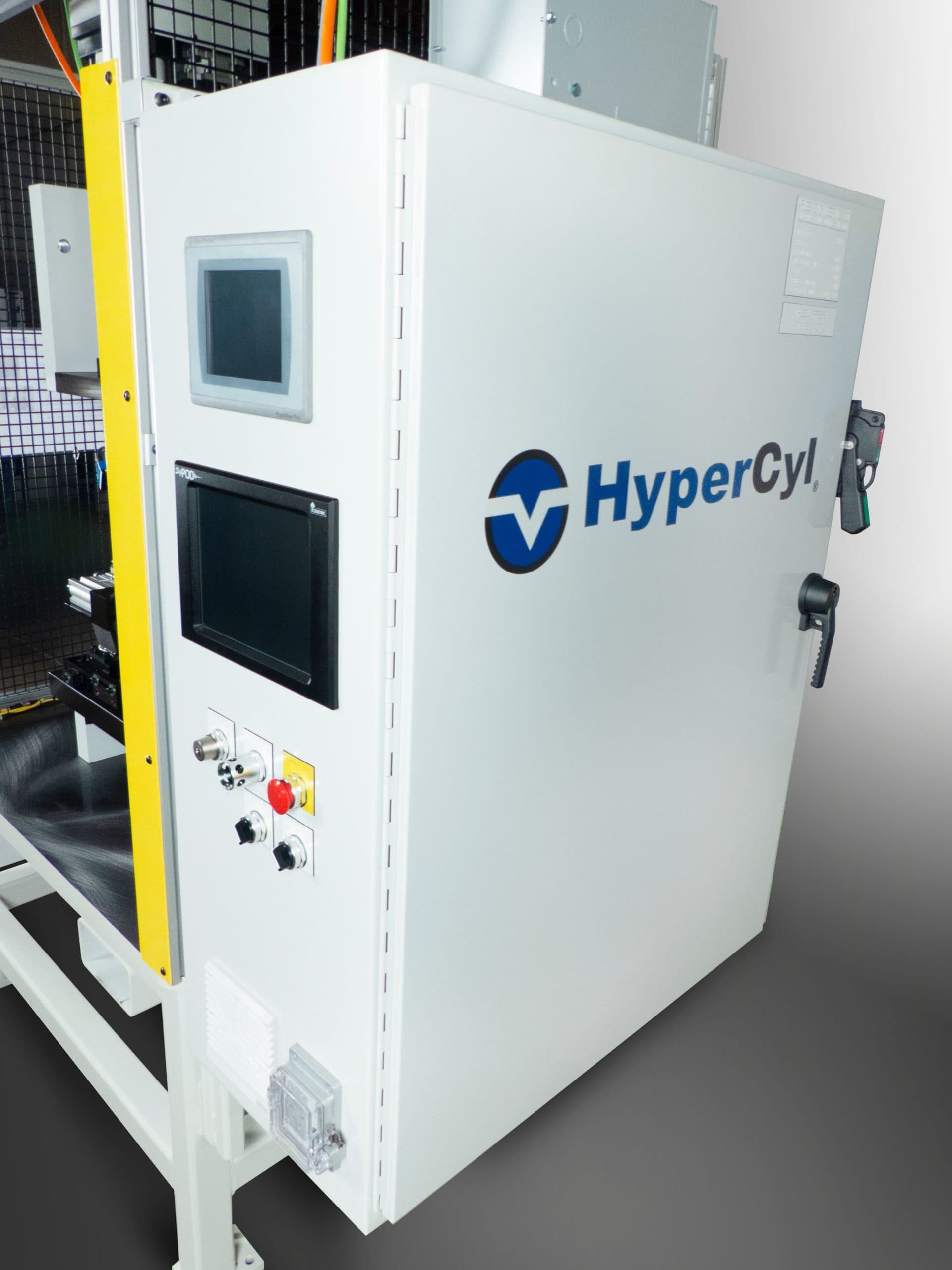

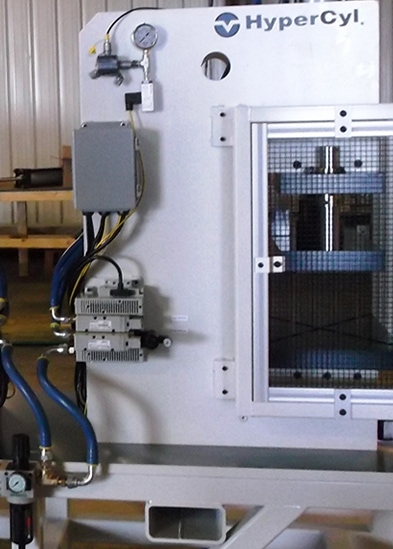

At Aries Engineering / HyperCyl (AEC), we specialize in the manufacture of hydra-pneumatic components and equipment for assembly and forming applications. We offer a variety of press systems, including H-frame presses.

Our standard H-frame presses are available in 1-ton to 50-ton sizes with unguided, two-column, or four-column guided bolsters. They have cylinder mounting plates, upper and lower bolsters, and tooling plates that are constructed of A36 steel and Blanchard ground. The columns are made from 100,000 tensile, 1045 ground polished, and chromed steel. The frames can be disassembled for customer machining or modification.

We can also create custom H-frame presses, up to 200 tons of force, to meet highly unique or specific customer needs. Custom finishing options include black oxide coating, nickel coating, and Polane painting.

Our larger H-frame presses systems use Superbolts to secure the plates and main posts. This design element reduces the amount of torque required compared to conventional fasteners without sacrificing durability in the face of immense forces. They also undergo a rigorous finite element analysis (FEA) process to verify they exhibit minimal deflection. In doing so, we ensure our systems offer high accuracy and precision, long tooling life, and less downtime.

To learn more about our H-frame presses and how they can benefit your operations, contact us or request a quote today.