HPS SERIES

LIMITED LIFETIME WARRANTY*

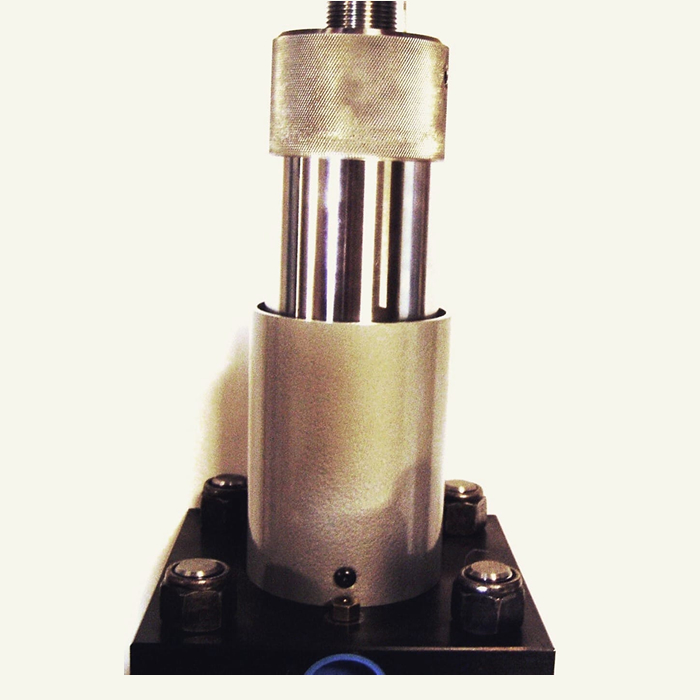

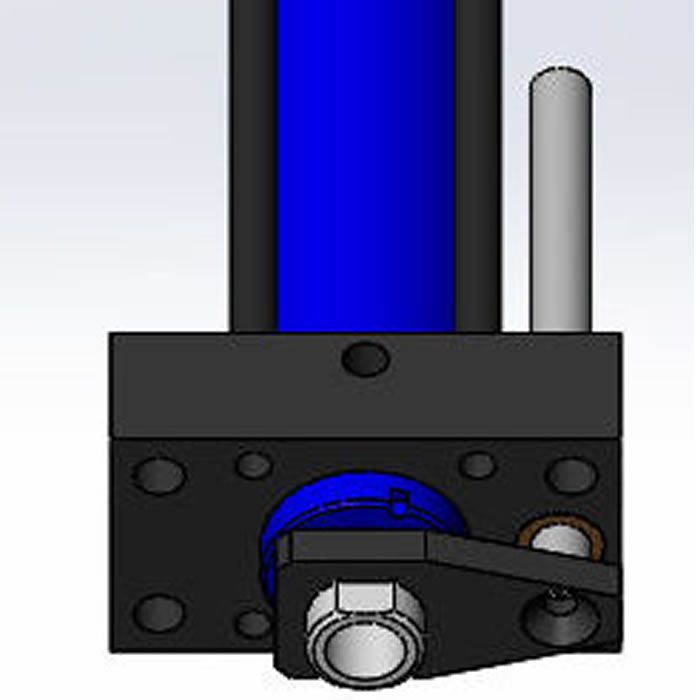

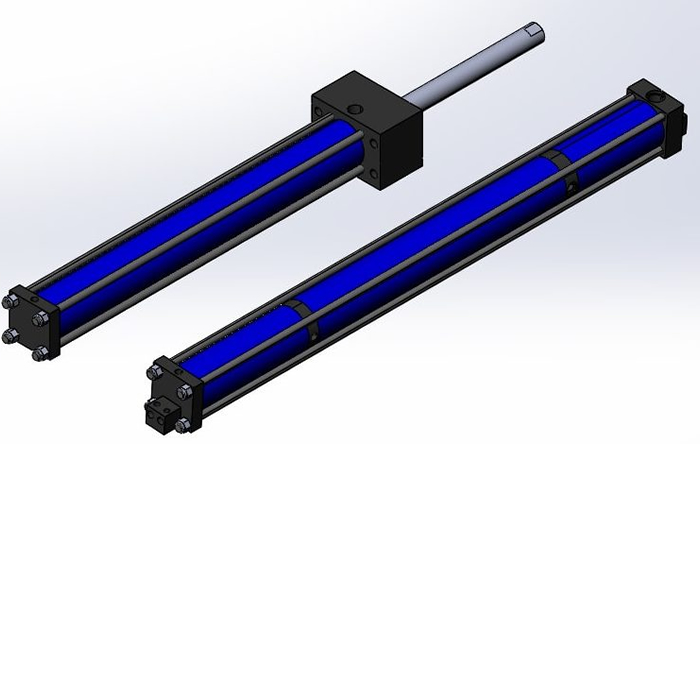

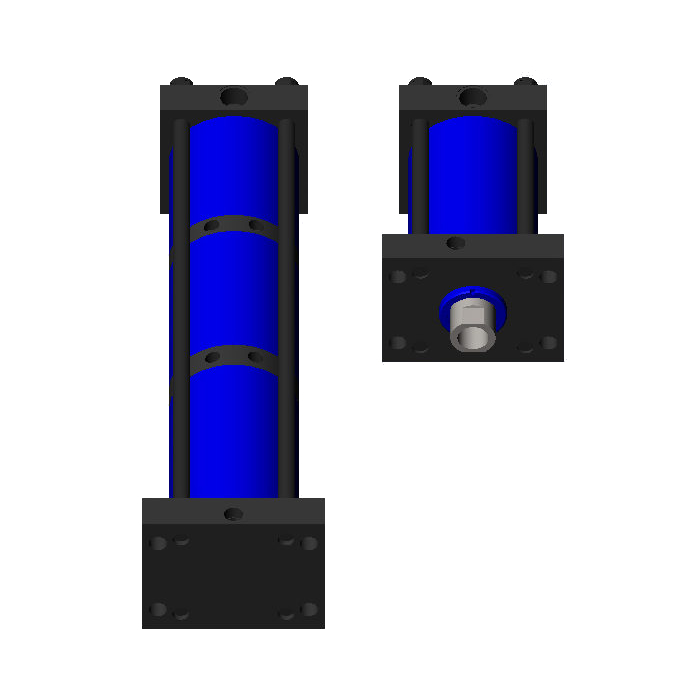

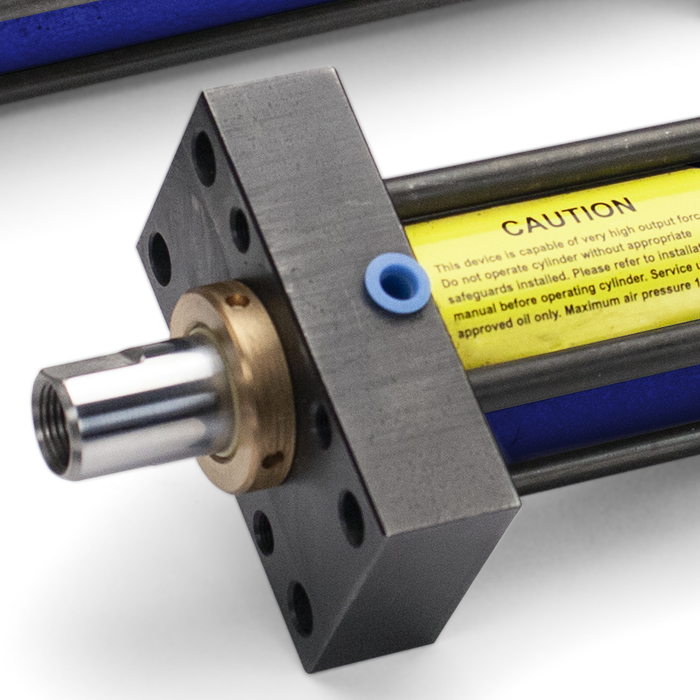

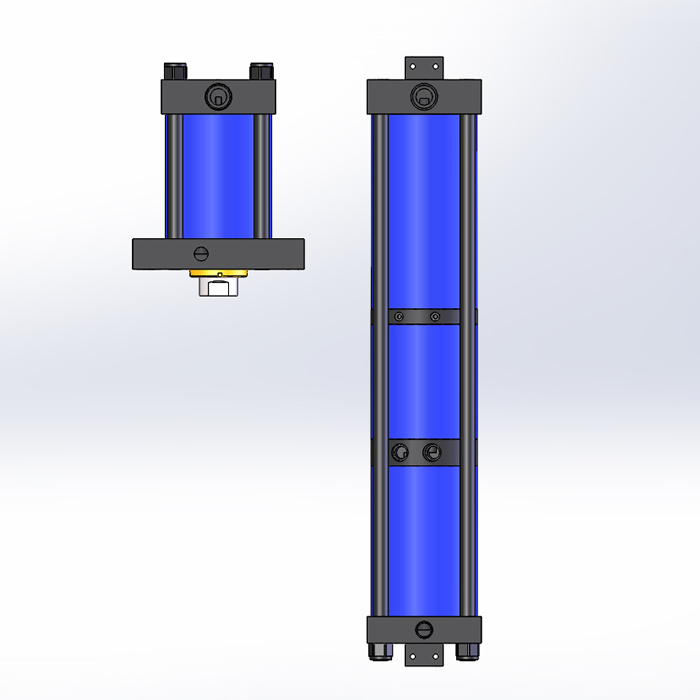

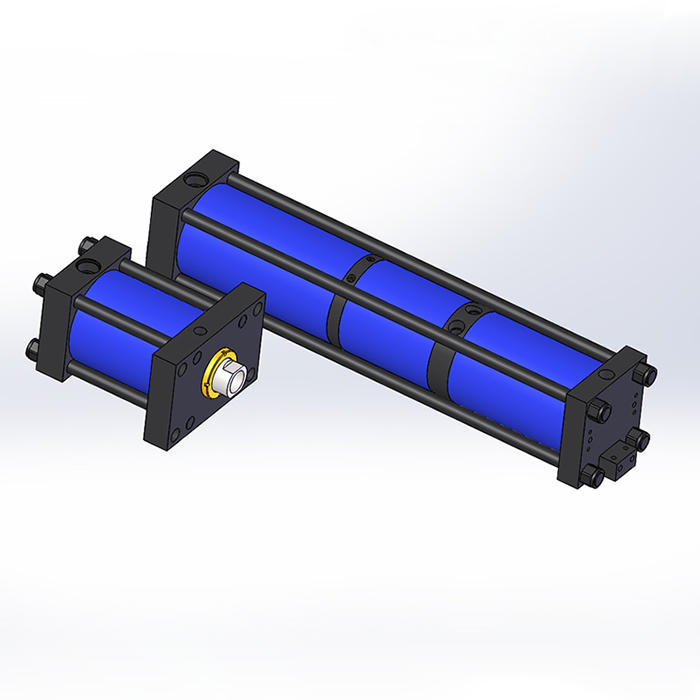

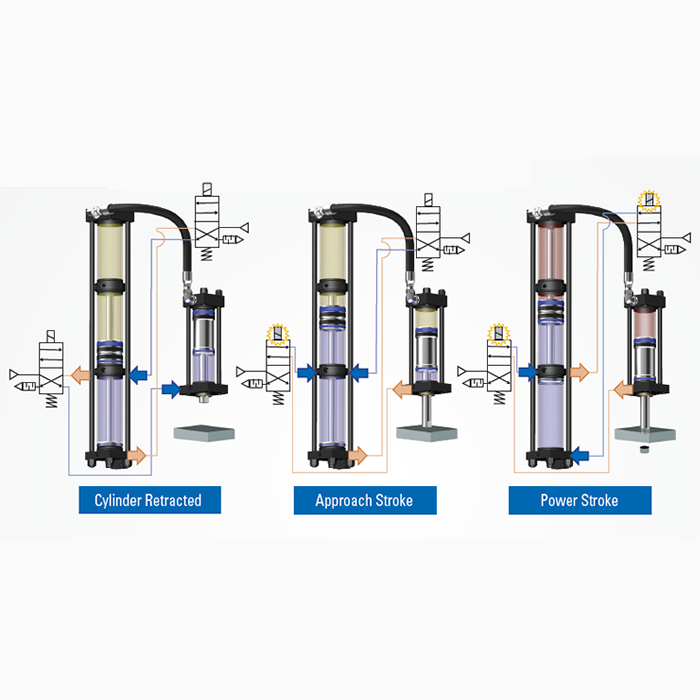

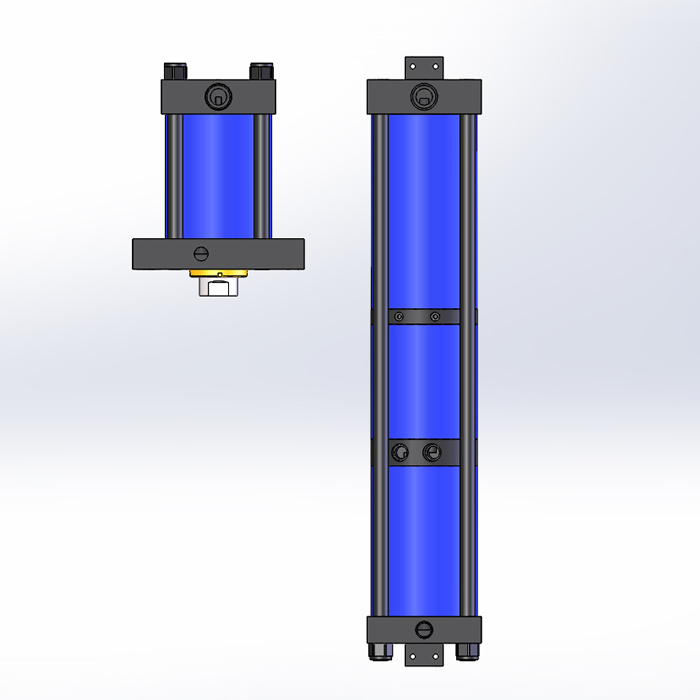

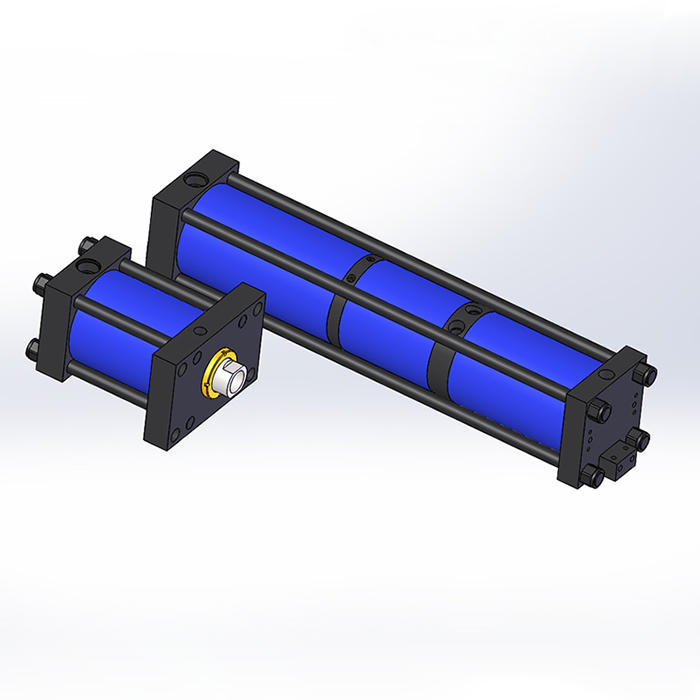

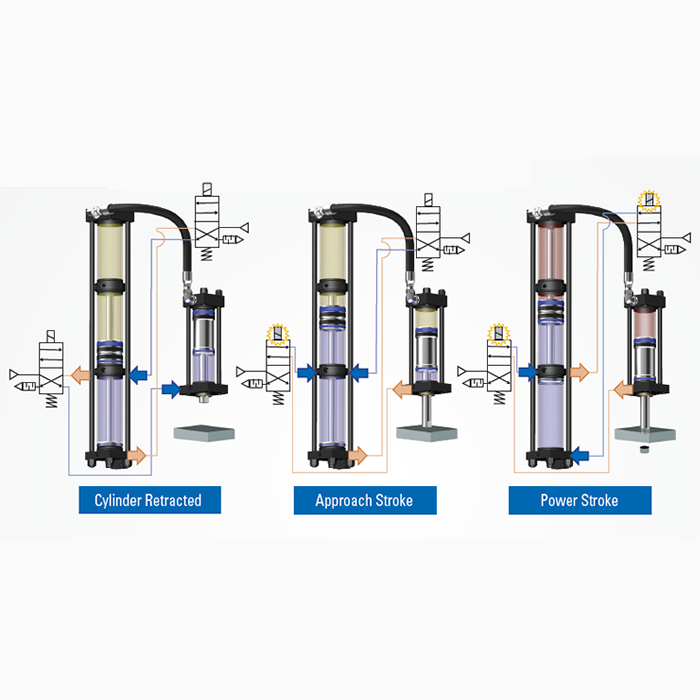

The HPS Series design provides a very compact package where space is limited or where strokes are long. The “HPS” Series satellite cylinder is a totally self-contained and cost-effective power source while permitting the working cylinder to be located up to 10 ft. from the booster/reservoir for ease of mounting/operation. Both components may be mounted in any position or attitude. Multiple working cylinders can be operated with a single booster/reservoir unit, application dependent.

Standard designs available in sizes from 1-Ton to 200-Tons. Up to 8.00″ stroke and 1.00″ power stroke available with standard designs. Customized stroke and power stroke lengths are available upon request with up to 24.00″ of Total Stroke and 6.00″ Power Stroke depending on application specifications.

Advantages:

- Multiple mounting configurations available

- Wide selections on strokes

- Most overall options available in a given series

- Initiation of power stroke anywhere within the total stroke

- Custom strokes available

- Custom rod ends available

- AVAILABILITY: 4-6 WEEKS STANDARD, EXPEDITE AVAILABLE

(CALL FOR SPECIFIC AVAILABILITY) - MODEL: HPS-XX-X.XX-X.XX-FH-XXXX

- Total Strokes up to 24.00” [711mm] using 2.00” increments is standard

- Power Strokes up to 6.00” [50mm] using 0.25” increments is standard

- 2-piece Unit with Work Section and Booster connected via hydraulic hose – multiple fittings available; 45, 90, live swivel (robot-mounted applications). Individual components can be mounted in any position or attitude

- 670 lbs. – 400,000 lbs. [2.9N – 1,779kN] force range using up to 100 PSI [6.9 bar] shop air.

- Add the IntelliCyl option for Force & Distance monitoring

- Power Retract option (-PR, pull instead of push), Total Stroke Limiter option (-TSL, adjustable mechanical stop for repeatable distance), Up to (4) Work Sections connected to (1) Booster (-FH/2, FH/3, FH/4), NFPA mounting options

- Other options – Non-Rotate (-NR), Pneumatic Port positions 1-4, Rod Extensions, Rod thread pattern (male or female), ELT auto power stroke sensor, BSPP or “G” pneumatic porting, Fill Units, Pressure Switches, Remote Pressure Block (PB-1), Internal LVDT (-LT) or External LVDT(-LTI) and external Load Cell (-LC)

| Sell Sheet: | HPS Sell Sheet |

|---|---|

| Functional Description: | HPS Functional Description |

| Hose-Fitting Specs: | HPS Hose-Fitting Specs Hose Specifications |

| Fill and Vent Procedures: | Using HFP-1 Fill Unit Using HFP-2 Fill Unit |

| Cylinder Component and Seal Callout: | Cylinder Seal Replacement Instructions |

| Approved Pneumatic Schematics: | 2-Pos Spring Return 2-Pos Spring Return ELT 2-Pos Spring Return with PT Sensor 2-Pos Spring Return with 2 Hand No Tie Down 3-Pos Open Center 3-Pos Open Center with Rod Lock |

| Troubleshooting: | Various Problem Solutions Serial Number Location |

1 Tons Force

HPS-1-2.00-.50-FH.dwg

HPS-1-2.00-.75-FH.dwg

HPS-1-2.00-1.00-FH.dwg

HPS-1-4.00-.25-FH.dwg

HPS-1-4.00-.50-FH.dwg

HPS-1-4.00-.75-FH.dwg

HPS-1-4.00-1.00-FH.dwg

HPS-1-6.00-.25-FH.dwg

HPS-1-6.00-.50-FH.dwg

HPS-1-6.00-.75-FH.dwg

HPS-1-6.00-1.00-FH.dwg

HPS-1-8.00-.25-FH.dwg

HPS-1-8.00-.50-FH.dwg

HPS-1-8.00-.75-FH.dwg

HPS-1-8.00-1.00-FH.dwg

2 Tons Force

HPS-2-2.00-.50-FH.dwg

HPS-2-2.00-.75-FH.dwg

HPS-2-2.00-1.00-FH.dwg

HPS-2-4.00-.25-FH.dwg

HPS-2-4.00-.50-FH.dwg

HPS-2-4.00-.75-FH.dwg

HPS-2-4.00-1.00-FH.dwg

HPS-2-6.00-.25-FH.dwg

HPS-2-6.00-.50-FH.dwg

HPS-2-6.00-.75-FH.dwg

HPS-2-6.00-1.00-FH.dwg

HPS-2-8.00-.25-FH.dwg

HPS-2-8.00-.50-FH.dwg

HPS-2-8.00-.75-FH.dwg

HPS-2-8.00-1.00-FH.dwg

4 Tons Force

HPS-4-2.00-.50-FH.dwg

HPS-4-2.00-.75-FH.dwg

HPS-4-2.00-1.00-FH.dwg

HPS-4-4.00-.25-FH.dwg

HPS-4-4.00-.50-FH.dwg

HPS-4-4.00-.75-FH.dwg

HPS-4-4.00-1.00-FH.dwg

HPS-4-6.00-.25-FH.dwg

HPS-4-6.00-.50-FH.dwg

HPS-4-6.00-.75-FH.dwg

HPS-4-6.00-1.00-FH.dwg

HPS-4-8.00-.25-FH.dwg

HPS-4-8.00-.50-FH.dwg

HPS-4-8.00-.75-FH.dwg

HPS-4-8.00-1.00-FH.dwg

8 Tons Force

HPS-8-2.00-.50-FH.dwg

HPS-8-2.00-.75-FH.dwg

HPS-8-2.00-1.00-FH.dwg

HPS-8-4.00-.25-FH.dwg

HPS-8-4.00-.50-FH.dwg

HPS-8-4.00-.75-FH.dwg

HPS-8-4.00-1.00-FH.dwg

HPS-8-6.00-.25-FH.dwg

HPS-8-6.00-.50-FH.dwg

HPS-8-6.00-.75-FH.dwg

HPS-8-6.00-1.00-FH.dwg

HPS-8-8.00-.25-FH.dwg

HPS-8-8.00-.50-FH.dwg

HPS-8-8.00-.75-FH.dwg

HPS-8-8.00-1.00-FH.dwg

10 Tons Force

HPS-10-2.00-.50-FH.dwg

HPS-10-2.00-.75-FH.dwg

HPS-10-2.00-1.00-FH.dwg

HPS-10-4.00-.25-FH.dwg

HPS-10-4.00-.50-FH.dwg

HPS-10-4.00-.75-FH.dwg

HPS-10-4.00-1.00-FH.dwg

HPS-10-6.00-.25-FH.dwg

HPS-10-6.00-.50-FH.dwg

HPS-10-6.00-.75-FH.dwg

HPS-10-6.00-1.0-FH.dwg

HPS-10-8.00-.25-FH.dwg

HPS-10-8.00-.50-FH.dwg

HPS-10-8.00-.75-FH.dwg

HPS-10-8.00-1.0-FH.dwg

15 Tons Force

HPS-15-2.00-.50-FH.dwg

HPS-15-2.00-.75-FH.dwg

HPS-15-2.00-1.00-FH.dwg

HPS-15-4.00-.25-FH.dwg

HPS-15-4.00-.50-FH.dwg

HPS-15-4.00-.75-FH.dwg

HPS-15-4.00-1.00-FH.dwg

HPS-15-6.00-.25-FH.dwg

HPS-15-6.00-.50-FH.dwg

HPS-15-6.00-.75-FH.dwg

HPS-15-6.00-1.00-FH.dwg

HPS-15-8.00-.25-FH.dwg

HPS-15-8.00-.50-FH.dwg

HPS-15-8.00-.75-FH.dwg

HPS-15-8.00-1.00-FH.dwg

20 Tons Force

HPS-20-2.00-.50-FH.dwg

HPS-20-2.00-.75-FH.dwg

HPS-20-2.00-1.00-FH.dwg

HPS-20-4.00-.25-FH.dwg

HPS-20-4.00-.50-FH.dwg

HPS-20-4.00-.75-FH.dwg

HPS-20-4.00-1.00-FH.dwg

HPS-20-6.00-.25-FH.dwg

HPS-20-6.00-.50-FH.dwg

HPS-20-6.00-.75-FH.dwg

HPS-20-6.00-1.00-FH.dwg

HPS-20-8.00-.25-FH.dwg

HPS-20-8.00-.50-FH.dwg

HPS-20-8.00-.75-FH.dwg

HPS-20-8.00-1.00-FH.dwg

30 Tons Force

HPS-30-2.00-.50-FH.dwg

HPS-30-2.00-.75-FH.dwg

HPS-30-2.00-1.00-FH.dwg

HPS-30-4.00-.25-FH.dwg

HPS-30-4.00-.50-FH.dwg

HPS-30-4.00-.75-FH.dwg

HPS-30-4.00-1.00-FH.dwg

HPS-30-6.00-.25-FH.dwg

HPS-30-6.00-.50-FH.dwg

HPS-30-6.00-.75-FH.dwg

HPS-30-6.00-1.00-FH.dwg

HPS-30-8.00-.25-FH.dwg

HPS-30-8.00-.50-FH.dwg

HPS-30-8.00-.75-FH.dwg

HPS-30-8.00-1.00-FH.dwg

40 Tons Force

50 Tons Force

HPS-50-2.00-.50-FH.dwg

HPS-50-2.00-.75-FH.dwg

HPS-50-2.00-1.00-FH.dwg

HPS-50-4.00-.25-FH.dwg

HPS-50-4.00-.50-FH.dwg

HPS-50-4.00-.75-FH.dwg

HPS-50-4.00-1.00-FH.dwg

HPS-50-6.00-.25-FH.dwg

HPS-50-6.00-.50-FH.dwg

HPS-50-6.00-.75-FH.dwg

HPS-50-6.00-1.00-FH.dwg

HPS-50-8.00-.25-FH.dwg

HPS-50-8.00-.50-FH.dwg

HPS-50-8.00-.75-FH.dwg

HPS-50-8.00-1.00-FH.dwg

60 Tons Force

75 Tons Force

HPS-75-2.00-.50-FH.dwg

HPS-75-2.00-.75-FH.dwg

HPS-75-2.00-1.00-FH.dwg

HPS-75-4.00-.25-FH.dwg

HPS-75-4.00-.50-FH.dwg

HPS-75-4.00-.75-FH.dwg

HPS-75-4.00-1.00-FH.dwg

HPS-75-6.00-.25-FH.dwg

HPS-75-6.00-.50-FH.dwg

HPS-75-6.00-.75-FH.dwg

HPS-75-6.00-1.00-FH.dwg

HPS-75-8.00-.25-FH.dwg

HPS-75-8.00-.50-FH.dwg

HPS-75-8.00-.75-FH.dwg

HPS-75-8.00-1.00-FH.dwg

1 Tons Force

HPS-1-2.00-.50-FH.step

HPS-1-2.00-.75-FH.step

HPS-1-2.00-1.00-FH.step

HPS-1-4.00-.25-FH.step

HPS-1-4.00-.50-FH.step

HPS-1-4.00-.75-FH.step

HPS-1-4.00-1.00-FH.step

HPS-1-6.00-.25-FH.step

HPS-1-6.00-.50-FH.step

HPS-1-6.00-.75-FH.step

HPS-1-6.00-1.00-FH.step

HPS-1-8.00-.25-FH.step

HPS-1-8.00-.50-FH.step

HPS-1-8.00-.75-FH.step

HPS-1-8.00-1.00-FH.step

2 Tons Force

HPS-2-2.00-.50-FH.step

HPS-2-2.00-.75-FH.step

HPS-2-2.00-1.00-FH.step

HPS-2-4.00-.25-FH.step

HPS-2-4.00-.50-FH.step

HPS-2-4.00-.75-FH.step

HPS-2-4.00-1.00-FH.step

HPS-2-6.00-.25-FH.step

HPS-2-6.00-.50-FH.step

HPS-2-6.00-.75-FH.step

HPS-2-6.00-1.00-FH.step

HPS-2-8.00-.25-FH.step

HPS-2-8.00-.50-FH.step

HPS-2-8.00-.75-FH.step

HPS-2-8.00-1.00-FH.step

4 Tons Force

HPS-4-2.00-.50-FH.step

HPS-4-2.00-.75-FH.step

HPS-4-2.00-1.00-FH.step

HPS-4-4.00-.25-FH.step

HPS-4-4.00-.50-FH.step

HPS-4-4.00-.75-FH.step

HPS-4-4.00-1.00-FH.step

HPS-4-6.00-.25-FH.step

HPS-4-6.00-.50-FH.step

HPS-4-6.00-.75-FH.step

HPS-4-6.00-1.00-FH.step

HPS-4-8.00-.25-FH.step

HPS-4-8.00-.50-FH.step

HPS-4-8.00-.75-FH.step

HPS-4-8.00-1.00-FH.step

8 Tons Force

HPS-8-2.00-.50-FH.step

HPS-8-2.00-.75-FH.step

HPS-8-2.00-1.00-FH.step

HPS-8-4.00-.25-FH.step

HPS-8-4.00-.50-FH.step

HPS-8-4.00-.75-FH.step

HPS-8-4.00-1.00-FH.step

HPS-8-6.00-.25-FH.step

HPS-8-6.00-.50-FH.step

HPS-8-6.00-.75-FH.step

HPS-8-6.00-1.00-FH.step

HPS-8-8.00-.25-FH.step

HPS-8-8.00-.50-FH.step

HPS-8-8.00-.75-FH.step

HPS-8-8.00-1.00-FH.step

10 Tons Force

HPS-10-2.00-.50-FH.step

HPS-10-2.00-.75-FH.step

HPS-10-2.00-1.00-FH.step

HPS-10-4.00-.25-FH.step

HPS-10-4.00-.50-FH.step

HPS-10-4.00-.75-FH.step

HPS-10-4.00-1.0-FH.step

HPS-10-6.00-.25-FH.step

HPS-10-6.00-.50-FH.step

HPS-10-6.00-.75-FH.step

HPS-10-6.00-1.00-FH.step

HPS-10-8.00-.25-FH.step

HPS-10-8.00-.50-FH.step

HPS-10-8.00-.75-FH.step

HPS-10-8.00-1.00-FH.step

15 Tons Force

HPS-15-2.00-.50-FH.step

HPS-15-2.00-.75-FH.step

HPS-15-2.00-1.00-FH.step

HPS-15-4.00-.25-FH.step

HPS-15-4.00-.50-FH.step

HPS-15-4.00-.75-FH.step

HPS-15-4.00-1.0-FH.step

HPS-15-6.00-.25-FH.step

HPS-15-6.00-.50-FH.step

HPS-15-6.00-.75-FH.step

HPS-15-6.00-1.00-FH.step

HPS-15-8.00-.25-FH.step

HPS-15-8.00-.50-FH.step

HPS-15-8.00-.75-FH.step

HPS-15-8.00-1.00-FH.step

20 Tons Force

HPS-20-2.00-.50-FH.step

HPS-20-2.00-.75-FH.step

HPS-20-2.00-1.00-FH.step

HPS-20-4.00-.25-FH.step

HPS-20-4.00-.50-FH.step

HPS-20-4.00-.75-FH.step

HPS-20-4.00-1.00-FH.step

HPS-20-6.00-.25-FH.step

HPS-20-6.00-.50-FH.step

HPS-20-6.00-.75-FH.step

HPS-20-6.00-1.00-FH.step

HPS-20-8.00-.25-FH.step

HPS-20-8.00-.50-FH.step

HPS-20-8.00-.75-FH.step

HPS-20-8.00-1.00-FH.step

30 Tons Force

HPS-30-2.00-.50-FH.step

HPS-30-2.00-.75-FH.step

HPS-30-2.00-1.00-FH.step

HPS-30-4.00-.25-FH.step

HPS-30-4.00-.50-FH.step

HPS-30-4.00-.75-FH.step

HPS-30-4.00-1.00-FH.step

HPS-30-6.00-.25-FH.step

HPS-30-6.00-.50-FH.step

HPS-30-6.00-.75-FH.step

HPS-30-6.00-1.00-FH.step

HPS-30-8.00-.25-FH.step

HPS-30-8.00-.50-FH.step

HPS-30-8.00-.75-FH.step

HPS-30-8.00-1.00-FH.step

40 Tons Force

50 Tons Force

HPS-50-2.00-.50-FH.step

HPS-50-2.00-.75-FH.step

HPS-50-2.00-1.00-FH.step

HPS-50-4.00-.25-FH.step

HPS-50-4.00-.50-FH.step

HPS-50-4.00-.75-FH.step

HPS-50-4.00-1.00-FH.step

HPS-50-6.00-.25-FH.step

HPS-50-6.00-.50-FH.step

HPS-50-6.00-.75-FH.step

HPS-50-6.00-1.00-FH.step

HPS-50-8.00-.25-FH.step

HPS-50-8.00-.50-FH.step

HPS-50-8.00-.75-FH.step

HPS-50-8.00-1.00-FH.step

60 Tons Force

75 Tons Force

HPS-75-2.00-.50-FH.step

HPS-75-2.00-.75-FH.step

HPS-75-2.00-1.00-FH.step

HPS-75-4.00-.25-FH.step

HPS-75-4.00-.50-FH.step

HPS-75-4.00-.75-FH.step

HPS-75-4.00-1.00-FH.step

HPS-75-6.00-.25-FH.step

HPS-75-6.00-.50-FH.step

HPS-75-6.00-.75-FH.step

HPS-75-6.00-1.00-FH.step

HPS-75-8.00-.25-FH.step

HPS-75-8.00-.50-FH.step

HPS-75-8.00-.75-FH.step

HPS-75-8.00-1.00-FH.step

RELATED OPTIONS

ACCESSORIES

(SWD) HEAVY DUTY DIGITAL PRESSURE SWITCH

(SW) HEAVY DUTY ANALOG PRESSURE SWITCH

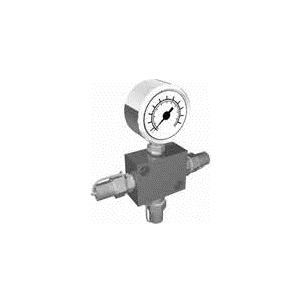

(G-01) HYDRAULIC GAGE KITS

(PHA-XX) HIGH PRESSURE HOSE ASSEMBLIES

(PB) PRESSURE BLOCK

(IC-1) PRESSURE COUPLING

(GA-1) GAGE ADAPTER COUPLING

(HFP-1) PNEUMATIC FILL UNIT

(HFP-2) MANUAL FILL UNIT

(PT)(ELT) SENSORS

(SIG) HYPERVIEW PRESS MONITORING SYSTEM

(PAF-XX) DIE SET MIS-ALIGNMENT COUPLINGS

(PAQ-XX) QUICK CHANGE DIE SET MIS-ALIGNMENT COUPLINGS

(NGT) PILOT OPERATED CHECK VALVE

(FC) PNEUMATIC FLOW CONTROL