HyperCyl Case Study: Control Arms and Snap Ring Solution

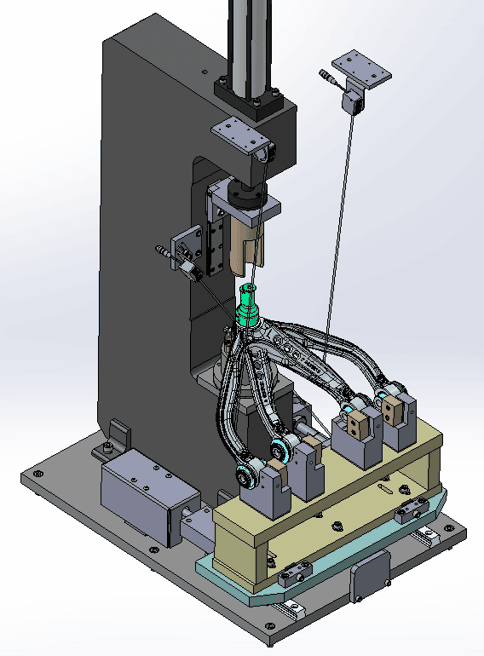

HyperCyl was tasked with an application that involved the installation of both bushings and ball joints on a control arm that included secondary retention of the ball joint. Thus, the HyperCyl patented Snap Ring Mechanism was developed in 2017.

What Control Arms Do

*Maintaining wheel alignment: The control arm helps to keep the wheels of the car aligned properly with the frame or body of the car. This is important for ensuring that the car drives smoothly and handles well.

*Absorbing shock: As the car travels over bumps and rough terrain, the control arm helps to absorb the shock and vibrations that are created. This helps to provide a comfortable ride for passengers and protects the car’s other components from damage.

*Supporting weight: The control arm supports the weight of the car and helps to distribute it evenly across the suspension system. This helps to prevent the car from leaning too much during turns or when going around corners.

*Controlling wheel movement: The control arm helps to control the movement of the wheel, ensuring that it stays in the correct position and doesn’t wobble or move excessively. This is important for maintaining the car’s stability and safety

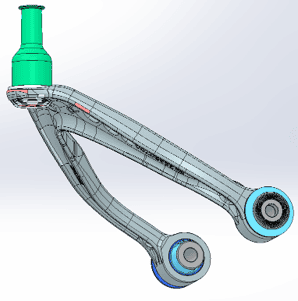

Anatomy of a Control Arm

*There exists an Upper Control Arm (UCA) and Lower Control Arm (LCA) with connecting tie-rods from each Ball-Joint to the steering system, be it a steering wheel for tractors/automobiles/lawnmowers or handlebars for 4-wheel ATV/UTV.

*Control Arms for all types of vehicles typically follow the same layout and arrangement; each requiring (2) Bushings and (1) Ball-Joint to stabilize the wheel and provide direct connection to your steering mechanism.

*Press Fitting the bushings is typical and the interference fit between the bushing and machined arm will retain the bushing in place. These can be pressed OUT when needed for vehicle maintenance.

*Ball-Joints require a similar Press-Fit into the cast/machined arm however automotive vehicles require a means of secondary retention due to vehicle safety standards and/or future replacement availability.

Secondary Retention of the Ball Joint

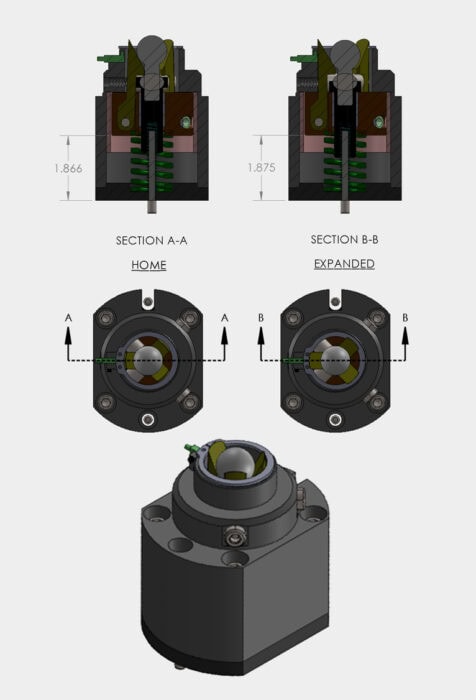

Secondary retention of the ball-joint can be accomplished by either a deformation of the ball-joint body, or by use of a heavy-duty retaining clip otherwise known as a snap-ring.

HyperCyl provide a means for installation of BOTH bushings and ball-joints but also can provide the means for secondary retention with our Patented Snap-Ring mechanism. This device is used in automated or semi-automated installation of the snap-rings for medium to high volume assembly production.

The Snap-Ring mechanism works as follows:

*The snap-ring is preloaded on top of nest (via robot or pick-n-place or manually by operator), the HyperCyl actuator extends down contacting the ball joint thereby pushing the ball joint bottom surface INTO the snap-ring.

*As the ball joint contacts the inner ball, the (3) fingers expand opening the snap ring as the pressing motion continues.

*Once the snap-ring is at the proper level the fingers release, and the snap-ring is properly located within the ball joint groove securing it from accidental removal. The ram can now retract to home, releasing the assembly for offload.

Fully patented in 2017, we have the experience and know-how to make your assembly efforts much less complicated with a standard design, or customized to fit your needs. Find out more how we can meet your application needs, call (734) 529-8855 or email [email protected].